Where to Get Acrylic Sheets: Your Ultimate Buying Guide

Looking for the best places to buy acrylic sheets? You’ve come to the right place. Whether you’re a DIY enthusiast, a professional fabricator, or simply need a sturdy, transparent material for your project, finding the right supplier is crucial. This comprehensive guide will walk you through everything you need to know about where to get acrylic sheets, from local retailers and online marketplaces to specialty suppliers, ensuring you get the best quality, price, and service. We’ll cover the different types of acrylic, factors to consider when purchasing, and tips for working with this versatile material. Our goal is to provide you with the expertise to make informed decisions and complete your projects successfully.

Understanding Acrylic Sheets: A Deep Dive

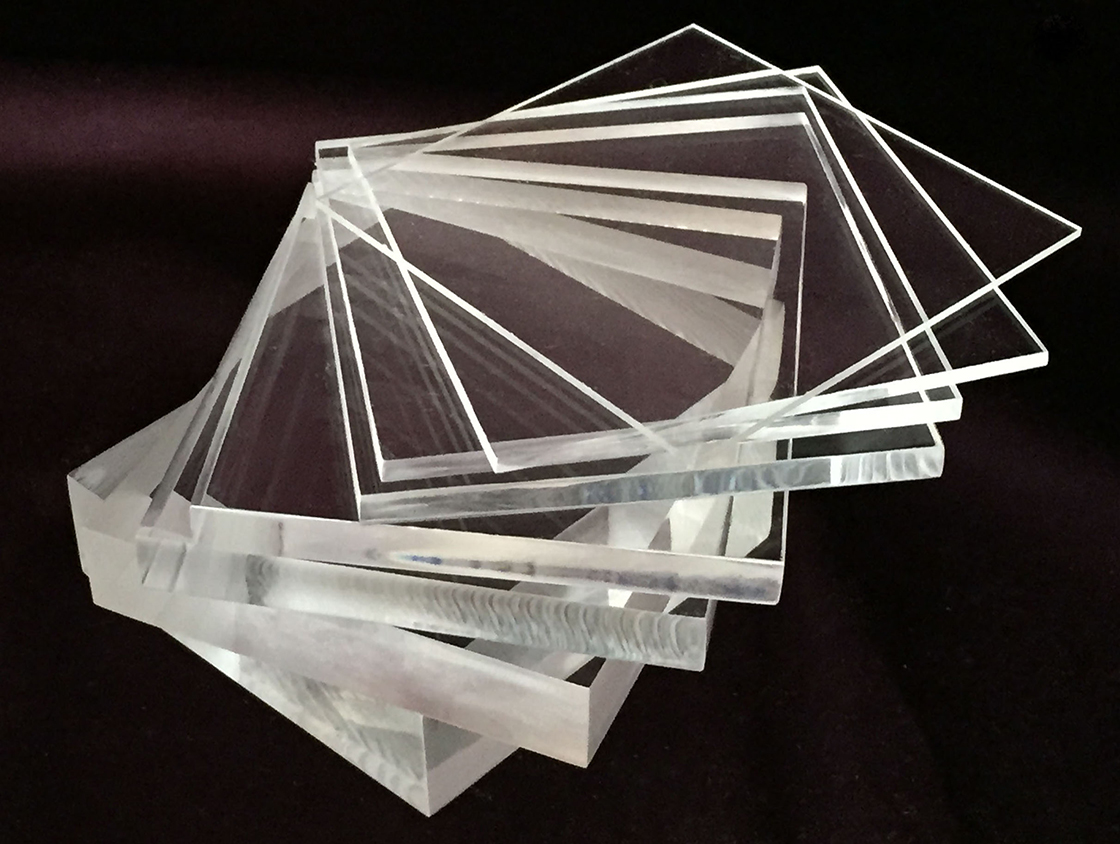

Acrylic sheets, also known as plexiglass, are a transparent thermoplastic often used as a lightweight and shatter-resistant alternative to glass. But the world of acrylic is more complex than you might think. There are different types, thicknesses, and grades, each suited for specific applications. Understanding these nuances is key to ensuring your project’s success.

Cast vs. Extruded Acrylic

The two main types of acrylic sheets are cast and extruded. Cast acrylic is produced by pouring liquid acrylic between two sheets of glass, creating a sheet with excellent optical clarity, chemical resistance, and thermal stability. Extruded acrylic, on the other hand, is manufactured by continuously pushing acrylic through a die. It’s generally more affordable and easier to cut, but it may have lower optical clarity and be more prone to scratching. The choice between the two often depends on the specific requirements of your project.

Cast Acrylic: Ideal for applications requiring high optical quality, intricate detailing, and resistance to chemicals and solvents. Examples include aquariums, signage, and high-end displays.

Extruded Acrylic: Suitable for general-purpose applications where cost is a primary concern and high optical clarity is not essential. Examples include window replacements, protective barriers, and simple DIY projects.

Acrylic Sheet Thickness and Size

Acrylic sheets come in a wide range of thicknesses, typically from 1/16 inch to several inches. The appropriate thickness depends on the size of the sheet and the intended application. Larger sheets require greater thickness to prevent bending or warping. It’s also crucial to consider the load-bearing capacity if the acrylic will be supporting any weight.

Sheet sizes also vary, with standard sizes like 4×8 feet being common. However, many suppliers offer custom cutting services to meet your specific needs. When planning your project, always factor in the material thickness and size to minimize waste and ensure structural integrity.

Grades of Acrylic

Not all acrylic is created equal. Different grades of acrylic exist, each with varying levels of quality and performance. Virgin acrylic, made from 100% new materials, offers the best optical clarity, strength, and UV resistance. Recycled acrylic, while more sustainable, may have slight imperfections or reduced performance characteristics. Understanding the grade of acrylic is critical for applications where aesthetics and durability are paramount.

Top Places Where to Get Acrylic Sheets

Now that you understand the different types of acrylic sheets, let’s explore the best places where to get acrylic sheets. Your options range from large home improvement stores to specialized online suppliers. Each option has its own advantages and disadvantages, so consider your specific needs and priorities when making your choice.

1. Home Improvement Stores: Convenience and Accessibility

Large home improvement stores like Home Depot and Lowe’s are a convenient option for buying acrylic sheets. They typically stock a limited range of sizes and thicknesses, primarily extruded acrylic. This can be a good option for small DIY projects or when you need acrylic quickly.

Pros:

- Convenient and easily accessible

- Immediate availability

- Good for small projects

Cons:

- Limited selection of sizes and thicknesses

- Primarily extruded acrylic

- May not offer custom cutting services

- Higher prices compared to specialty suppliers

2. Local Plastics Suppliers: Expertise and Customization

Local plastics suppliers specialize in acrylic and other plastic materials. They typically offer a wider range of acrylic types, thicknesses, and sizes than home improvement stores. They also often provide custom cutting services and expert advice.

Pros:

- Wider selection of acrylic types and thicknesses

- Custom cutting services

- Expert advice and support

- Competitive pricing

Cons:

- May require more research to find a reputable supplier

- Potentially longer lead times for custom orders

3. Online Marketplaces: Variety and Price Comparison

Online marketplaces like Amazon and eBay offer a vast selection of acrylic sheets from various suppliers. This can be a good option for comparing prices and finding specific sizes or colors. However, it’s essential to carefully vet the seller and read reviews before making a purchase.

Pros:

- Wide variety of options

- Easy price comparison

- Convenient online ordering

Cons:

- Quality can vary significantly

- Shipping costs can be high

- Potential for misrepresentation or fraud

- Longer lead times due to shipping

4. Specialty Online Suppliers: Quality and Expertise

Specialty online suppliers focus specifically on plastics and acrylics. They typically offer the highest quality materials, expert advice, and a wide range of customization options. These suppliers often cater to professional fabricators and industrial clients.

Pros:

- Highest quality materials

- Expert advice and technical support

- Wide range of customization options

- Competitive pricing for bulk orders

Cons:

- May have higher minimum order quantities

- Potentially longer lead times for custom orders

- Shipping costs can be significant for large sheets

Leading Acrylic Sheet Suppliers: A Closer Look

Let’s take a look at some of the leading suppliers of acrylic sheets, both online and offline, to give you a better idea of your options.

TAP Plastics

TAP Plastics is a well-known supplier with multiple locations and a strong online presence. They offer a wide range of acrylic sheets, including cast and extruded, as well as custom cutting services. They are known for their knowledgeable staff and high-quality products.

ePlastics

ePlastics is a popular online supplier offering a vast selection of acrylic sheets, rods, and tubes. They provide detailed product information and technical support, making it easier to choose the right material for your project. They also offer custom cutting and fabrication services.

Aetna Plastics

Aetna Plastics is a large industrial supplier with a wide range of plastic materials, including acrylic sheets. They offer competitive pricing and fast shipping, making them a good option for bulk orders.

Factors to Consider When Choosing a Supplier

Choosing the right supplier is crucial for ensuring the success of your project. Here are some key factors to consider:

Quality of Materials

Ensure the supplier offers high-quality acrylic sheets that meet your specific requirements. Ask about the grade of acrylic and request samples if necessary.

Pricing and Payment Options

Compare prices from different suppliers and consider payment options. Some suppliers offer discounts for bulk orders or accept various payment methods.

Shipping and Delivery

Check the supplier’s shipping policies and delivery times. Consider shipping costs, especially for large sheets, and ensure the supplier offers adequate packaging to protect the acrylic during transit.

Customer Service and Support

Choose a supplier with excellent customer service and technical support. They should be able to answer your questions, provide expert advice, and assist with any issues that may arise.

Customization Options

If you require custom cutting or fabrication services, ensure the supplier offers these options and has the necessary equipment and expertise.

Working with Acrylic Sheets: Essential Tips

Once you’ve purchased your acrylic sheets, it’s essential to handle and work with them properly to avoid damage and ensure a professional finish. Here are some essential tips:

Cutting Acrylic Sheets

Acrylic sheets can be cut using various tools, including a table saw, jigsaw, or laser cutter. When using a table saw, use a blade designed for plastics and feed the material slowly to prevent chipping or cracking. A jigsaw can be used for curved cuts, but ensure the blade is sharp and the acrylic is properly supported. Laser cutting provides the cleanest and most precise cuts, but it requires specialized equipment.

Drilling Acrylic Sheets

When drilling acrylic sheets, use a drill bit designed for plastics and run the drill at a slow speed. Apply gentle pressure and avoid overheating the acrylic, which can cause it to crack. Back up the acrylic with a piece of wood to prevent splintering.

Cleaning Acrylic Sheets

Acrylic sheets can be cleaned with a soft cloth and a mild detergent. Avoid using abrasive cleaners or solvents, which can scratch or damage the surface. Use a dedicated acrylic cleaner for best results.

Protecting Acrylic Sheets

Protect acrylic sheets from scratches and damage by storing them in a safe place and covering them with a protective film when handling. Avoid placing heavy objects on top of acrylic sheets, which can cause them to bend or warp.

Advantages and Benefits of Using Acrylic Sheets

Acrylic sheets offer numerous advantages and benefits over other materials, making them a popular choice for a wide range of applications.

Lightweight and Durable

Acrylic sheets are significantly lighter than glass, making them easier to handle and install. They are also much more shatter-resistant, reducing the risk of breakage and injury.

Excellent Optical Clarity

Acrylic sheets offer excellent optical clarity, allowing for clear and unobstructed views. They are also available in various colors and tints to suit different applications.

Weather Resistance

Acrylic sheets are highly resistant to weathering, making them suitable for outdoor applications. They can withstand exposure to sunlight, rain, and temperature changes without degrading or discoloring.

Versatility

Acrylic sheets are versatile and can be easily cut, drilled, and formed to create various shapes and designs. They can be used in a wide range of applications, including signage, displays, windows, and furniture.

Real-World Value and Applications

The benefits of acrylic translate into significant real-world value across various industries and applications:

- Retail: Acrylic displays enhance product visibility and create an appealing shopping experience.

- Healthcare: Acrylic barriers provide protection and maintain hygiene in medical facilities.

- Transportation: Acrylic windows offer safety and clarity in vehicles and aircraft.

- Construction: Acrylic skylights and roofing provide natural light and weather resistance.

- DIY Projects: From picture frames to custom furniture, acrylic empowers creative endeavors.

Insightful Q&A Section

-

Q: What is the best way to clean acrylic sheets without scratching them?

A: Use a microfiber cloth and a specialized acrylic cleaner or a very mild soap and water solution. Avoid abrasive cleaners or paper towels.

-

Q: Can I use regular glue to bond acrylic sheets together?

A: No, regular glue will not create a strong bond with acrylic. Use a solvent-based acrylic adhesive or a specialized acrylic bonding agent.

-

Q: How can I prevent acrylic sheets from yellowing over time?

A: Choose acrylic sheets with UV protection and avoid exposing them to direct sunlight for extended periods.

-

Q: What is the maximum temperature acrylic sheets can withstand?

A: The maximum continuous service temperature for acrylic is around 180°F (82°C). Exceeding this temperature can cause the acrylic to soften or deform.

-

Q: Can I paint acrylic sheets?

A: Yes, you can paint acrylic sheets using acrylic paints specifically designed for plastics. Prepare the surface by cleaning and priming it before painting.

-

Q: What type of saw blade is best for cutting acrylic sheets?

A: A fine-tooth blade designed for plastics is best for cutting acrylic sheets. Avoid using blades with coarse teeth, which can chip or crack the acrylic.

-

Q: How do I remove scratches from acrylic sheets?

A: Minor scratches can be removed using a plastic polish and a soft cloth. For deeper scratches, you may need to use a series of progressively finer sandpaper grits followed by polishing.

-

Q: Are acrylic sheets recyclable?

A: Yes, acrylic sheets are recyclable, but recycling facilities may not always accept them. Check with your local recycling center to see if they accept acrylic.

-

Q: What are the common mistakes to avoid when working with acrylic sheets?

A: Common mistakes include using the wrong tools, applying too much pressure, overheating the acrylic, and using abrasive cleaners.

-

Q: How do I choose the right thickness of acrylic sheet for my project?

A: The appropriate thickness depends on the size of the sheet and the intended application. Consult with a supplier or refer to online resources for guidance.

Conclusion: Making the Right Choice for Your Acrylic Needs

Finding where to get acrylic sheets involves considering factors like material quality, price, customization, and supplier reliability. Whether you opt for the convenience of a home improvement store, the expertise of a local plastics supplier, or the vast selection of an online marketplace, remember to prioritize your project’s specific requirements. By carefully evaluating your options and following the tips outlined in this guide, you can confidently source the perfect acrylic sheets for your next endeavor.

Now that you’re armed with the knowledge of where to get acrylic sheets, we encourage you to share your own experiences or project ideas in the comments below. Or, if you’re ready to start a project, explore our advanced guide to acrylic fabrication techniques!