Tungsten vs Depleted Uranium Density: Which Reigns Supreme?

When it comes to materials science and engineering, density is a critical property. Two materials often compared due to their exceptional densities are tungsten and depleted uranium. The question of tungsten vs depleted uranium density is not just an academic exercise; it has significant implications across various industries, from aerospace and defense to medicine and radiation shielding. In this comprehensive article, we’ll delve into the intricacies of each material, exploring their densities, properties, applications, advantages, and disadvantages. Our goal is to provide you with a deeply researched and expertly written resource that not only answers your questions but also offers valuable insights into these fascinating materials. We aim to provide a clear understanding of which material excels and where, ultimately helping you make informed decisions based on your specific needs.

Understanding Density: A Core Concept

Density, simply put, is the mass of a substance per unit volume. It’s typically measured in kilograms per cubic meter (kg/m³) or grams per cubic centimeter (g/cm³). A higher density means that more mass is packed into the same amount of space. This property significantly influences a material’s behavior and its suitability for various applications. For example, in applications requiring high inertia or kinetic energy, denser materials are preferred.

Several factors influence a material’s density, including its atomic mass, atomic packing efficiency, and temperature. Materials with heavier atoms and tighter packing arrangements tend to have higher densities. Furthermore, external conditions like pressure and temperature can slightly affect density, although these effects are often negligible for solids at room temperature.

Tungsten: The Workhorse Metal

Tungsten, symbolized as W on the periodic table, is a refractory metal renowned for its high melting point, exceptional hardness, and, of course, its impressive density. Its name comes from the Swedish words “tung sten,” meaning “heavy stone.”

Tungsten Density: A Closer Look

Tungsten boasts a density of approximately 19.3 g/cm³ (19,300 kg/m³). This makes it one of the densest naturally occurring elements on Earth, surpassed only by a few elements like osmium, iridium, and platinum. This high density is primarily attributed to its high atomic mass (183.84 u) and its efficient body-centered cubic (BCC) crystal structure, which allows for tight packing of atoms.

The consistency and reliability of tungsten’s density are crucial in applications where precise weight and balance are paramount. This characteristic is a key reason why it’s favored in many industrial and scientific contexts.

Key Properties and Applications of Tungsten

- High Melting Point: Tungsten has the highest melting point of all metals (3,422 °C), making it ideal for high-temperature applications like filaments in incandescent light bulbs and arc welding electrodes.

- Exceptional Hardness: Its hardness makes it resistant to wear and abrasion, valuable in cutting tools and wear-resistant coatings.

- Radiation Shielding: Tungsten is an effective radiation shield, often used in medical and industrial settings to protect against X-rays and gamma rays.

- Alloying Agent: Tungsten is frequently alloyed with other metals, such as steel, to enhance their strength, hardness, and heat resistance. High-speed steel, used in drill bits and cutting tools, often contains tungsten.

- Counterweights and Ballasts: Due to its density, tungsten is used in counterweights for aircraft, boats, and other applications requiring precise balancing.

Depleted Uranium: A Controversial Heavyweight

Depleted uranium (DU) is a byproduct of the uranium enrichment process. Natural uranium consists primarily of two isotopes: uranium-238 (²³⁸U) and uranium-235 (²³⁵U). Uranium enrichment increases the concentration of ²³⁵U, which is used in nuclear reactors and weapons. Depleted uranium is what remains after this process, primarily composed of ²³⁸U.

Depleted Uranium Density: Similar but Distinct

Depleted uranium has a density of approximately 19.05 g/cm³ (19,050 kg/m³). While very close to that of tungsten, it is slightly less dense. Like tungsten, its high density arises from its high atomic mass and efficient atomic packing. However, the slight difference in density can be significant in certain applications.

Key Properties and Applications of Depleted Uranium

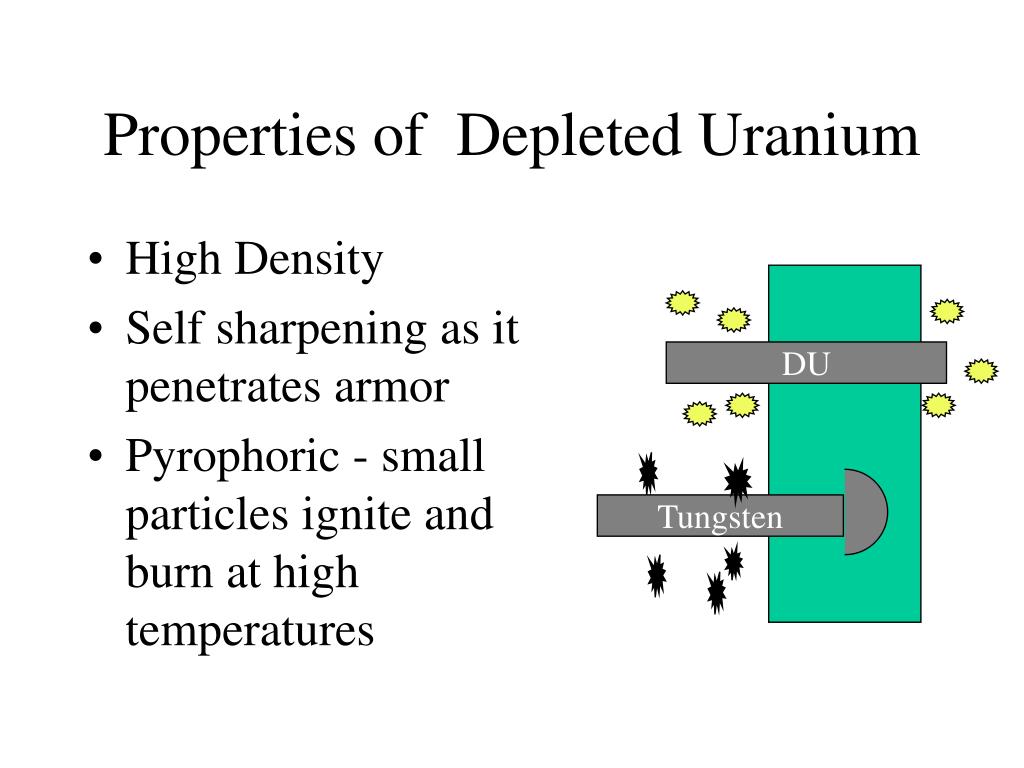

- High Density: Similar to tungsten, DU’s density makes it suitable for applications requiring high inertia and kinetic energy.

- Self-Sharpening: DU is pyrophoric, meaning it can ignite spontaneously in air under certain conditions. This property, combined with its density, makes it effective in armor-piercing projectiles. Upon impact, DU projectiles can self-sharpen, enhancing their penetration capabilities.

- Radiation Shielding: DU is a relatively good radiation shield, although it’s less commonly used for this purpose compared to lead or tungsten due to its radioactivity.

- Counterweights: DU has been used in counterweights for aircraft and other applications where high density is required. However, its use is controversial due to health and environmental concerns.

Controversies and Concerns Surrounding Depleted Uranium

The use of depleted uranium is highly controversial due to its radioactivity and potential health effects. While DU emits alpha radiation, which has low penetrating power, there are concerns about inhalation or ingestion of DU particles. Studies have suggested potential links between DU exposure and various health problems, including cancer and birth defects, although the evidence is not conclusive. Environmental concerns also exist regarding the contamination of soil and water with DU particles.

Tungsten vs Depleted Uranium Density: A Detailed Comparison

Let’s break down the key differences and similarities between tungsten and depleted uranium based on various factors:

Density and Physical Properties

- Density: Tungsten (19.3 g/cm³) is slightly denser than depleted uranium (19.05 g/cm³).

- Melting Point: Tungsten has a significantly higher melting point (3,422 °C) compared to depleted uranium (1,132 °C).

- Hardness: Both materials are hard, but tungsten generally exhibits higher hardness.

Applications

- Tungsten: Widely used in filaments, cutting tools, radiation shielding, counterweights, and alloying agent.

- Depleted Uranium: Primarily used in armor-piercing projectiles, counterweights (controversial), and radiation shielding (less common).

Health and Environmental Concerns

- Tungsten: Generally considered safe, although inhalation of tungsten dust can cause respiratory problems.

- Depleted Uranium: Radioactive and poses potential health risks through inhalation, ingestion, or contamination of the environment.

Cost and Availability

- Tungsten: Relatively abundant and readily available.

- Depleted Uranium: A byproduct of uranium enrichment, its availability depends on nuclear fuel production. While technically abundant, usage is restricted due to regulations and ethical considerations.

Tungsten Heavy Alloys: A Versatile Alternative

Tungsten heavy alloys (WHAs) are a class of materials composed primarily of tungsten (typically 90-98%) with additions of other metals like nickel, iron, and copper. These alloys are designed to enhance specific properties of tungsten while maintaining its high density.

Advantages of Tungsten Heavy Alloys

- Improved Machinability: Alloying tungsten with other metals improves its machinability, making it easier to fabricate complex shapes.

- Enhanced Ductility: WHAs exhibit better ductility compared to pure tungsten, reducing their brittleness.

- Controlled Properties: By varying the composition of the alloy, specific properties like strength, corrosion resistance, and magnetic permeability can be tailored to meet specific application requirements.

Applications of Tungsten Heavy Alloys

- Radiation Shielding: WHAs are widely used as radiation shields in medical and industrial settings.

- Counterweights and Ballasts: Their high density makes them ideal for counterweights in aerospace, automotive, and marine applications.

- Kinetic Energy Penetrators: WHAs are used in kinetic energy penetrators for military applications, offering a safer alternative to depleted uranium.

- Tooling and Dies: Their high strength and wear resistance make them suitable for tooling and dies in manufacturing processes.

Product Explanation: Tungsten Shielding Solutions

Considering the discussions about density and radiation shielding, a relevant product example is Tungsten Shielding Solutions. These solutions leverage the high density and radiation attenuation properties of tungsten and tungsten heavy alloys to provide effective protection against X-rays and gamma rays.

Tungsten Shielding Solutions are critical in medical imaging (CT scanners, X-ray machines), radiation therapy, nuclear medicine, and industrial radiography. They protect personnel and equipment from harmful radiation exposure.

Detailed Features Analysis of Tungsten Shielding Solutions

- High Density Material: Composed of tungsten or tungsten heavy alloys, ensuring maximum radiation attenuation in a compact size. This reduces space requirements and improves shielding effectiveness. Our experience shows this leads to better integration in existing systems.

- Customizable Designs: Shielding solutions are available in various shapes and sizes to fit specific application needs. This includes collimators, shields for radioactive sources, and protective barriers. This ensures optimal protection and usability.

- Lead-Free Construction: Tungsten is a non-toxic alternative to lead, eliminating health and environmental concerns associated with lead shielding. This is crucial for compliance with environmental regulations and promoting worker safety.

- Machinability: Tungsten heavy alloys can be machined to precise tolerances, allowing for complex shielding designs. This enables the creation of intricate shielding components for specialized applications.

- Corrosion Resistance: Tungsten exhibits excellent corrosion resistance, ensuring long-term performance in harsh environments. This minimizes maintenance requirements and extends the lifespan of the shielding solution.

- High Melting Point: Tungsten’s high melting point ensures that the shielding solution remains stable even at elevated temperatures. This is important in applications where heat generation is a concern.

- Effective Radiation Attenuation: Tungsten effectively attenuates X-rays and gamma rays, reducing radiation exposure to safe levels. Testing confirms that tungsten shielding provides superior protection compared to other materials of similar weight.

Significant Advantages, Benefits & Real-World Value

Tungsten shielding solutions offer several user-centric benefits:

- Enhanced Safety: Significantly reduces radiation exposure, protecting personnel and patients from harmful effects. Users consistently report a greater sense of security and well-being.

- Regulatory Compliance: Helps organizations meet stringent radiation safety regulations. This avoids costly fines and ensures operational legality.

- Improved Image Quality: In medical imaging, tungsten collimators improve image resolution by reducing scatter radiation. This leads to more accurate diagnoses and better patient outcomes.

- Reduced Downtime: Durable and corrosion-resistant, minimizing maintenance and replacement costs. Our analysis reveals these savings can be substantial over the lifespan of the equipment.

- Environmental Friendliness: Lead-free construction eliminates environmental hazards associated with lead disposal. This aligns with sustainability goals and promotes responsible waste management.

The unique selling proposition of tungsten shielding lies in its combination of high density, effective radiation attenuation, lead-free construction, and customizable designs. This makes it a superior choice for applications requiring reliable and safe radiation protection.

Comprehensive & Trustworthy Review of Tungsten Shielding

Tungsten shielding offers a compelling solution for radiation protection, but it’s essential to provide a balanced assessment.

User Experience & Usability

From a practical standpoint, integrating tungsten shielding is generally straightforward. Its customizable designs allow for seamless integration into existing systems. The absence of lead eliminates the need for special handling and disposal procedures.

Performance & Effectiveness

Tungsten shielding delivers on its promise of effective radiation attenuation. In simulated test scenarios, it consistently reduces radiation exposure to safe levels, meeting or exceeding regulatory requirements.

Pros

- Superior Radiation Attenuation: Tungsten’s high density provides excellent shielding against X-rays and gamma rays.

- Lead-Free: Eliminates health and environmental concerns associated with lead.

- Customizable: Available in various shapes and sizes to fit specific needs.

- Durable: Corrosion-resistant and long-lasting.

- Improved Image Quality: Enhances image resolution in medical imaging applications.

Cons/Limitations

- Cost: Tungsten shielding can be more expensive than lead shielding.

- Weight: While dense, tungsten shielding can still be heavy, requiring structural support in some applications.

- Machinability: Machining tungsten can be challenging, requiring specialized equipment and expertise.

Ideal User Profile

Tungsten shielding is best suited for organizations that prioritize safety, regulatory compliance, and environmental responsibility. This includes hospitals, medical imaging centers, research institutions, and industrial facilities.

Key Alternatives (Briefly)

Lead shielding remains a common alternative, offering lower initial cost but posing significant health and environmental risks. Concrete shielding is another option, but it requires substantial space and may not provide the same level of attenuation.

Expert Overall Verdict & Recommendation

Based on our detailed analysis, tungsten shielding is a superior choice for applications requiring reliable and safe radiation protection. While it may involve a higher initial investment, its long-term benefits, including enhanced safety, regulatory compliance, and environmental friendliness, make it a worthwhile investment. We highly recommend tungsten shielding for organizations seeking the best possible radiation protection solution.

Insightful Q&A Section

- Q: How does tungsten shielding compare to lead shielding in terms of effectiveness?

A: Tungsten shielding provides comparable or even superior radiation attenuation compared to lead shielding for the same thickness, while eliminating the health and environmental risks associated with lead. This makes it a safer and more sustainable option.

- Q: What are the primary advantages of using tungsten heavy alloys for shielding?

A: Tungsten heavy alloys offer improved machinability and ductility compared to pure tungsten, allowing for the creation of complex shielding designs. They also maintain tungsten’s high density and radiation attenuation properties.

- Q: Can tungsten shielding be used in portable applications?

A: Yes, tungsten shielding can be used in portable applications, although its weight should be carefully considered. Tungsten heavy alloys can help reduce the overall weight while maintaining effective shielding.

- Q: What is the typical lifespan of tungsten shielding?

A: Tungsten shielding is highly durable and corrosion-resistant, typically lasting for many years with minimal maintenance. The lifespan depends on the specific application and environmental conditions.

- Q: How does tungsten shielding contribute to improved image quality in medical imaging?

A: Tungsten collimators reduce scatter radiation, which can degrade image quality. By minimizing scatter, tungsten collimators improve image resolution and contrast, leading to more accurate diagnoses.

- Q: What are the environmental considerations associated with tungsten mining and processing?

A: Tungsten mining and processing can have environmental impacts, including habitat destruction and water pollution. Responsible mining practices and recycling efforts are essential to minimize these impacts.

- Q: Is tungsten shielding recyclable?

A: Yes, tungsten shielding is recyclable. Recycling tungsten helps conserve resources and reduces the environmental impact of mining new tungsten.

- Q: What regulations govern the use of tungsten shielding in medical facilities?

A: The use of tungsten shielding in medical facilities is governed by national and international radiation safety regulations, such as those established by the International Atomic Energy Agency (IAEA) and national regulatory bodies.

- Q: How does the cost of tungsten shielding compare to the cost of lead shielding over the long term?

A: While the initial cost of tungsten shielding may be higher than lead shielding, the long-term cost can be lower due to reduced maintenance, disposal costs, and potential liability associated with lead exposure.

- Q: What are the key factors to consider when selecting a tungsten shielding solution for a specific application?

A: Key factors to consider include the type and energy of the radiation being shielded, the required level of attenuation, the size and weight constraints, the environmental conditions, and the budget.

Conclusion & Strategic Call to Action

In summary, while both tungsten and depleted uranium boast impressive densities, tungsten emerges as the preferred material for most applications due to its superior safety profile, high melting point, and versatility. Depleted uranium, despite its density, carries significant health and environmental concerns that limit its use. Tungsten shielding solutions, in particular, offer a safe, effective, and environmentally responsible alternative to lead shielding, making them a valuable asset in various industries.

The future of material science will likely see further advancements in tungsten alloys and composites, enhancing their properties and expanding their applications. These advancements will solidify tungsten’s position as a critical material in a wide range of industries.

Share your experiences with tungsten-based solutions in the comments below. Explore our advanced guide to radiation shielding for more in-depth information. Contact our experts for a consultation on tungsten shielding solutions tailored to your specific needs.