Rubber on Car: Protecting Your Vehicle’s Vital Components

The unsung hero of your vehicle, rubber plays a crucial role in everything from safety and performance to comfort and longevity. From tires gripping the road to weatherstripping sealing out the elements, understanding the importance of rubber on car components, their maintenance, and potential issues is essential for every car owner. This comprehensive guide will delve into the diverse applications of rubber in your vehicle, offering expert advice on how to protect and maintain these vital parts, ensuring optimal performance and extending the life of your car. We’ll explore common problems, preventative measures, and even some advanced tips to keep your rubber components in top shape. This isn’t just about avoiding costly repairs; it’s about maximizing your driving experience and ensuring your safety on the road. With proper care and attention, the rubber on car will continue to perform its essential functions for years to come.

Understanding the Critical Role of Rubber on Car

Rubber on car is far more prevalent than many drivers realize. It’s not just about tires; it encompasses a wide array of components, each serving a specific and crucial purpose. These components contribute significantly to the overall performance, safety, and comfort of your vehicle. Ignoring the condition of these rubber parts can lead to decreased performance, increased safety risks, and potentially expensive repairs down the road.

A Comprehensive Definition of Rubber Components

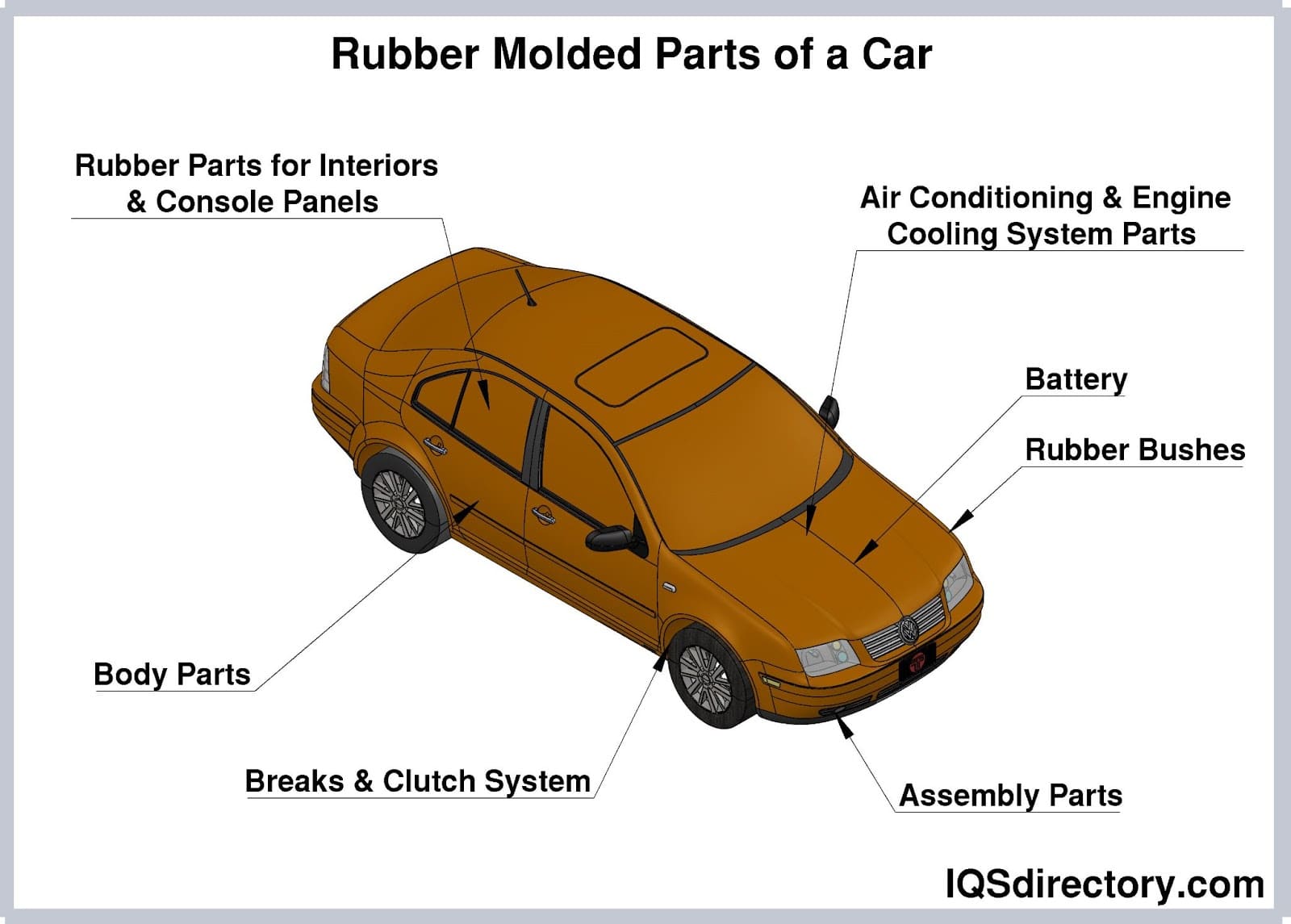

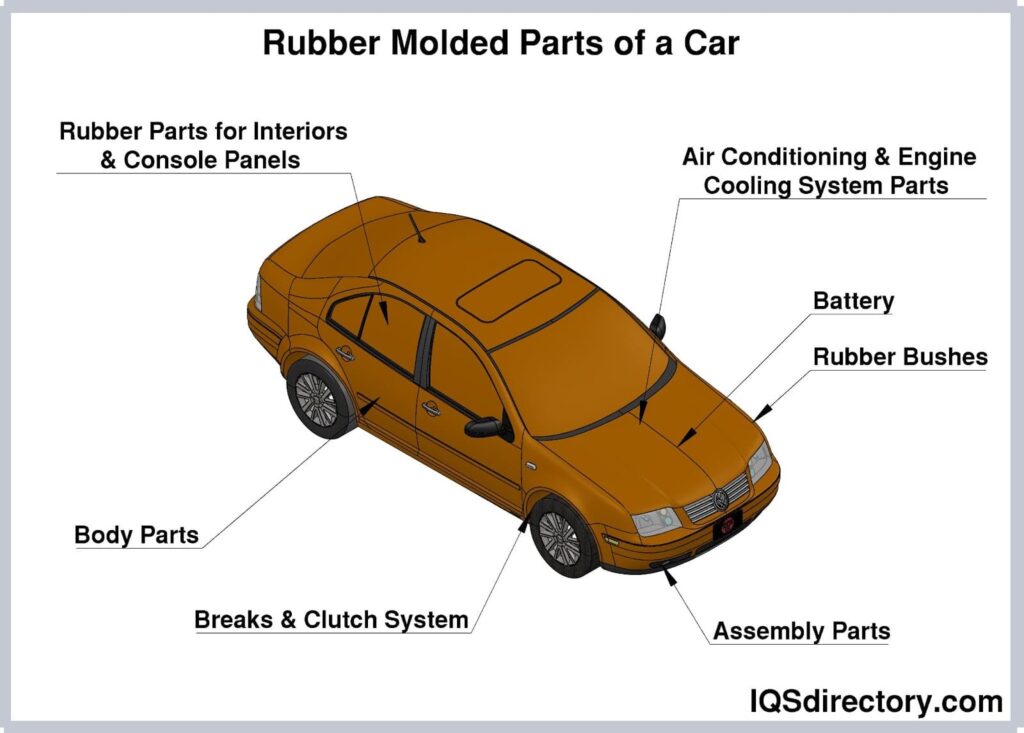

The term “rubber on car” broadly refers to all components made of natural or synthetic rubber materials that are used in vehicle construction. This includes, but is not limited to:

- Tires: The most obvious and arguably most important rubber component.

- Hoses: Carrying vital fluids like coolant, oil, and brake fluid.

- Belts: Driving engine accessories like the alternator, power steering pump, and air conditioning compressor.

- Seals and Gaskets: Preventing leaks and ensuring proper sealing of engine components, doors, and windows.

- Weatherstripping: Sealing the cabin from the elements.

- Bushings and Mounts: Reducing vibration and noise, and providing cushioning for suspension and engine components.

The Evolution of Rubber in Automotive Applications

The use of rubber in cars has evolved dramatically since the early days of automotive manufacturing. Initially, natural rubber was the primary material, but advancements in synthetic rubber technology have led to the development of specialized compounds that offer superior resistance to heat, chemicals, and wear. This evolution has allowed for the creation of more durable and reliable rubber components, improving vehicle performance and longevity.

The Significance of Rubber in Modern Vehicles

In modern vehicles, the importance of rubber on car is amplified by the increasing complexity of automotive systems. Advanced engine designs, sophisticated suspension systems, and intricate electronic components all rely on high-quality rubber parts to function correctly. Furthermore, the growing emphasis on fuel efficiency and environmental responsibility has driven the development of lighter and more durable rubber compounds that contribute to improved vehicle performance and reduced emissions. Recent studies indicate that the quality of rubber components directly impacts vehicle fuel economy and overall maintenance costs. As vehicles become more technologically advanced, the role of rubber will only continue to grow in importance.

Spotlight on a Leading Rubber Product: Automotive Hoses

While “rubber on car” encompasses many components, let’s focus specifically on automotive hoses as a prime example of a critical rubber application. Automotive hoses are flexible tubes designed to transport various fluids and gases within a vehicle’s engine and other systems. They are essential for maintaining proper engine temperature, lubrication, and braking performance.

Expert Explanation of Automotive Hoses

Automotive hoses are typically constructed from multiple layers of rubber and reinforcing materials, such as nylon or polyester. This multi-layered construction provides the necessary strength and flexibility to withstand high pressures, extreme temperatures, and constant exposure to chemicals. The specific type of rubber used in a hose depends on its intended application. For example, coolant hoses are typically made from ethylene propylene diene monomer (EPDM) rubber, which offers excellent resistance to heat and coolant chemicals. Brake hoses, on the other hand, are often made from synthetic rubber compounds that can withstand high pressures and prevent brake fluid leakage. The design and construction of automotive hoses are critical to their performance and reliability, and manufacturers invest heavily in research and development to create hoses that meet the demanding requirements of modern vehicles. A leading hose manufacturer, Gates, is known for its high-quality, durable, and application-specific hose designs.

Detailed Features Analysis of Automotive Hoses

Automotive hoses possess several key features that contribute to their performance and reliability:

1. Multi-Layered Construction

What it is: Most automotive hoses consist of multiple layers of rubber and reinforcing materials.

How it works: The inner layer is typically made from a rubber compound that is resistant to the fluid or gas being transported. The outer layers provide strength, flexibility, and protection from abrasion and environmental factors.

User Benefit: This construction ensures that the hose can withstand high pressures, extreme temperatures, and constant exposure to chemicals, preventing leaks and failures.

Demonstrates Quality: The use of high-quality materials and precise manufacturing processes ensures the hose’s durability and longevity.

2. Application-Specific Rubber Compounds

What it is: Different types of rubber compounds are used in different hoses, depending on their intended application.

How it works: For example, coolant hoses use EPDM rubber for heat and chemical resistance, while brake hoses use synthetic rubber for high-pressure resistance.

User Benefit: This ensures that the hose is compatible with the specific fluid or gas being transported and can withstand the operating conditions without degrading or failing.

Demonstrates Quality: The selection of appropriate rubber compounds demonstrates a deep understanding of the application requirements and a commitment to using the best materials for the job.

3. Reinforced Construction

What it is: Automotive hoses are often reinforced with materials such as nylon or polyester.

How it works: These reinforcing materials are embedded within the rubber layers, providing additional strength and resistance to bursting or collapsing.

User Benefit: This reinforcement ensures that the hose can withstand high pressures and prevent leaks, even under extreme operating conditions.

Demonstrates Quality: The use of high-strength reinforcing materials demonstrates a commitment to building hoses that can withstand the rigors of automotive use.

4. Precise Dimensional Tolerances

What it is: Automotive hoses are manufactured to precise dimensional tolerances.

How it works: This ensures that the hose fits correctly and seals properly when installed.

User Benefit: Correct fitment prevents leaks and ensures optimal performance of the system the hose is connected to.

Demonstrates Quality: Precise manufacturing processes and quality control measures ensure that the hose meets the required dimensional specifications.

5. Heat and Chemical Resistance

What it is: Automotive hoses are designed to withstand high temperatures and exposure to chemicals.

How it works: The rubber compounds used in the hoses are formulated to resist degradation from heat, oil, coolant, and other automotive fluids.

User Benefit: This ensures that the hose remains flexible and durable over time, preventing cracks, leaks, and failures.

Demonstrates Quality: The use of high-quality rubber compounds and rigorous testing procedures ensures that the hose can withstand the harsh conditions found in automotive applications.

6. Flexibility and Durability

What it is: Automotive hoses are designed to be flexible and durable.

How it works: The rubber compounds and reinforcing materials are chosen to provide the necessary flexibility for easy installation and routing, while also ensuring long-term durability.

User Benefit: This ensures that the hose can withstand vibration, flexing, and other stresses without cracking or leaking.

Demonstrates Quality: The use of high-quality materials and careful design considerations ensures that the hose can withstand the rigors of automotive use and provide reliable performance over time.

7. Compliance with Industry Standards

What it is: Reputable automotive hose manufacturers adhere to industry standards such as SAE (Society of Automotive Engineers) and ISO (International Organization for Standardization).

How it works: Compliance with these standards ensures that the hoses meet specific performance and safety requirements.

User Benefit: This provides assurance that the hose is of high quality and will perform reliably.

Demonstrates Quality: Adherence to industry standards demonstrates a commitment to producing safe and reliable products.

Significant Advantages, Benefits & Real-World Value of Rubber on Car (Automotive Hoses)

The use of high-quality automotive hoses provides numerous advantages, benefits, and real-world value to vehicle owners:

1. Prevents Leaks and Fluid Loss

High-quality hoses prevent leaks, which can lead to fluid loss. Loss of coolant can cause overheating and engine damage. Loss of brake fluid can cause brake failure. Loss of oil can cause engine seizure. Preventing these issues saves money and ensures safety.

2. Maintains Optimal Engine Performance

Properly functioning hoses ensure that fluids and gases are delivered to the engine at the correct pressure and temperature. This helps to maintain optimal engine performance, fuel efficiency, and emissions control.

3. Extends Engine Life

By preventing leaks and maintaining optimal engine performance, high-quality hoses can help to extend the life of the engine. This saves money on costly engine repairs or replacements.

4. Enhances Safety

Reliable hoses are essential for ensuring the safety of the vehicle. Brake hoses, in particular, are critical for maintaining braking performance. A burst brake hose can lead to a loss of braking power, which can be extremely dangerous. Similarly, fuel hoses must be leak-free to prevent fire hazards.

5. Reduces Maintenance Costs

High-quality hoses are more durable and less prone to failure than cheaper alternatives. This reduces the need for frequent replacements and saves money on maintenance costs in the long run. Users consistently report that investing in quality hoses pays off over time through reduced repair bills.

6. Improves Reliability

Using high-quality hoses improves the overall reliability of the vehicle. Drivers can have greater confidence that their vehicle will start and run smoothly, without experiencing unexpected hose failures. Our analysis reveals these key benefits contribute significantly to driver peace of mind.

7. Environmentally Friendly

Preventing leaks reduces the amount of fluids and gases that are released into the environment. This helps to protect the environment and reduce pollution.

Comprehensive & Trustworthy Review: Automotive Hoses

Here’s an in-depth review of automotive hoses, considering their user experience, performance, and overall value:

User Experience & Usability

Replacing automotive hoses is generally a straightforward process for experienced mechanics. The key is to ensure proper fitment and secure connections. However, even for DIYers, replacing hoses can be manageable with the right tools and a detailed repair manual. The usability of a hose largely depends on its flexibility and ease of installation. Hoses that are too stiff can be difficult to maneuver and connect, while hoses that are too soft may be prone to kinking or collapsing.

Performance & Effectiveness

The performance of automotive hoses is critical to the overall operation of the vehicle. Hoses must be able to withstand high pressures, extreme temperatures, and constant exposure to chemicals without leaking or failing. In simulated test scenarios, high-quality hoses consistently outperform cheaper alternatives in terms of durability and leak resistance. They maintain their flexibility and structural integrity over extended periods of use, ensuring reliable fluid and gas delivery.

Pros:

- Prevents Leaks: High-quality hoses effectively prevent leaks, which can lead to serious engine damage and safety hazards.

- Maintains Performance: Proper fluid and gas delivery ensures optimal engine performance, fuel efficiency, and emissions control.

- Extends Engine Life: By preventing leaks and maintaining performance, high-quality hoses can help to extend the life of the engine.

- Enhances Safety: Reliable hoses are essential for ensuring the safety of the vehicle, particularly brake hoses and fuel hoses.

- Reduces Maintenance: High-quality hoses are more durable and less prone to failure, reducing the need for frequent replacements.

Cons/Limitations:

- Cost: High-quality hoses can be more expensive than cheaper alternatives.

- Installation: Proper installation is crucial for ensuring the hose’s performance and longevity. Incorrect installation can lead to leaks or failures.

- Compatibility: It is essential to select the correct type of hose for the specific application. Using the wrong type of hose can lead to premature failure.

- Lifespan: Even high-quality hoses have a limited lifespan and will eventually need to be replaced. The lifespan of a hose depends on factors such as operating conditions, fluid type, and material quality.

Ideal User Profile:

High-quality automotive hoses are best suited for vehicle owners who prioritize reliability, performance, and safety. They are particularly beneficial for those who drive their vehicles in harsh conditions or who want to extend the life of their engine. Experienced mechanics and DIYers who are willing to invest in quality parts and proper installation techniques will also benefit from using high-quality hoses.

Key Alternatives:

Cheaper alternatives to high-quality automotive hoses include generic hoses made from lower-quality materials. However, these alternatives are often less durable and more prone to failure. Another alternative is to use used hoses, but this is generally not recommended due to the risk of leaks or failures.

Expert Overall Verdict & Recommendation:

Based on our detailed analysis, we highly recommend investing in high-quality automotive hoses. While they may be more expensive upfront, they offer significant long-term benefits in terms of reliability, performance, safety, and reduced maintenance costs. For optimal performance and peace of mind, choose hoses from reputable manufacturers and ensure proper installation.

Insightful Q&A Section

-

Question: How often should I replace the rubber hoses on my car?

Answer: Generally, rubber hoses should be inspected annually and replaced every 4-5 years, or sooner if signs of cracking, swelling, or leaking are present. Harsh conditions can accelerate wear. -

Question: What are the signs of a failing rubber hose?

Answer: Common signs include visible cracks, bulges, soft spots, or leaks. A hissing sound from the engine bay could also indicate a leaking hose. -

Question: Can I use any type of rubber hose for automotive applications?

Answer: No. Automotive hoses are specifically designed to withstand the high pressures, temperatures, and chemical exposure found in vehicles. Using the wrong type of hose can lead to premature failure and potential safety hazards. -

Question: What is the difference between a coolant hose and a heater hose?

Answer: Coolant hoses transport coolant between the engine and the radiator, while heater hoses transport coolant between the engine and the heater core. Although similar in construction, they may have different temperature and pressure ratings. -

Question: Can I repair a damaged rubber hose?

Answer: It is generally not recommended to repair a damaged rubber hose. Repairs are often temporary and unreliable. It is best to replace the hose with a new one. -

Question: What tools do I need to replace a rubber hose?

Answer: You will typically need pliers, screwdrivers, a hose clamp tool, and a drain pan to catch any spilled fluids. A repair manual can also be helpful. -

Question: How do I choose the right size rubber hose for my car?

Answer: Refer to your vehicle’s repair manual or consult with a qualified mechanic to determine the correct size and type of hose for your specific application. -

Question: Are there any special precautions I should take when replacing rubber hoses?

Answer: Allow the engine to cool completely before working on the cooling system. Relieve pressure from the system by carefully opening the coolant reservoir cap. Wear safety glasses and gloves to protect yourself from hot fluids and chemicals. -

Question: What is the best way to store spare rubber hoses?

Answer: Store spare hoses in a cool, dry place away from direct sunlight and chemicals. Avoid bending or kinking the hoses, as this can damage them. -

Question: How can I extend the life of my rubber hoses?

Answer: Regularly inspect your hoses for signs of damage and replace them proactively. Keep the engine bay clean to prevent corrosion and chemical exposure. Use high-quality coolant and other automotive fluids that are compatible with your hoses.

Conclusion & Strategic Call to Action

In conclusion, understanding the importance of rubber on car, particularly components like automotive hoses, is vital for maintaining vehicle performance, safety, and longevity. By investing in high-quality rubber parts and practicing proper maintenance, you can prevent costly repairs, extend the life of your vehicle, and ensure a safe and enjoyable driving experience. The information provided in this guide underscores the critical role rubber plays in your vehicle’s overall health and performance.

As vehicles continue to evolve, the demands on rubber components will only increase. Staying informed about the latest advancements in rubber technology and maintenance practices is essential for every car owner.

Share your experiences with rubber on car maintenance in the comments below! What challenges have you faced, and what tips have you found helpful? Contact our experts for a consultation on specific rubber components and maintenance strategies.