Plastic Acrylic: The Definitive Expert Guide to Properties, Uses, and Value

Plastic acrylic, also known as polymethyl methacrylate (PMMA), is a versatile synthetic polymer lauded for its exceptional clarity, durability, and weather resistance. This comprehensive guide delves into the depths of plastic acrylic, providing an expert perspective on its properties, applications, advantages, and limitations. Whether you’re a designer, engineer, hobbyist, or simply curious about this remarkable material, this article will equip you with the knowledge you need to understand and appreciate the world of plastic acrylic.

We’ll explore its chemical makeup, manufacturing processes, diverse applications across industries, and a balanced review that highlights both its strengths and weaknesses. Our aim is to provide a 10x resource that goes beyond basic definitions, offering practical insights and expert advice to help you make informed decisions regarding the use of plastic acrylic in your projects.

Understanding Plastic Acrylic: A Deep Dive

Plastic acrylic is a transparent thermoplastic often used as a lightweight or shatter-resistant alternative to glass. Its chemical formula is (C5H8O2)n, where ‘n’ represents the number of repeating monomer units. This structure gives it unique properties that make it suitable for a wide range of applications.

History and Evolution of Acrylic

Acrylic polymers were first developed in the early 20th century. Otto Röhm, a German chemist, is credited with patenting the first process for polymerizing methyl methacrylate in 1934. This breakthrough led to the commercial production of acrylic sheets under various trade names, including Plexiglas and Lucite. Since then, acrylic has undergone continuous refinement, with advancements in manufacturing processes and formulations enhancing its properties and expanding its applications.

Core Concepts and Advanced Principles

At its core, plastic acrylic is a polymer formed through the polymerization of methyl methacrylate monomers. This process creates long chains of molecules that are tightly bound together, resulting in a strong and rigid material. The transparency of acrylic is due to its amorphous structure, which allows light to pass through without scattering. However, acrylic can also be modified with additives to create opaque or colored versions.

Advanced principles involve understanding the different grades of acrylic, each with specific properties tailored to particular applications. For example, cast acrylic is known for its superior optical clarity and resistance to scratching, while extruded acrylic is more cost-effective and easier to thermoform.

Importance and Current Relevance

Plastic acrylic remains highly relevant today due to its unique combination of properties. Its clarity makes it ideal for applications such as windows, displays, and lenses. Its durability and weather resistance make it suitable for outdoor signage, automotive parts, and marine applications. Furthermore, acrylic is recyclable, contributing to sustainable practices. Recent studies indicate a growing demand for acrylic in the construction and automotive industries, driven by its lightweight properties and design flexibility.

Leading Product: Acrylic Sheets

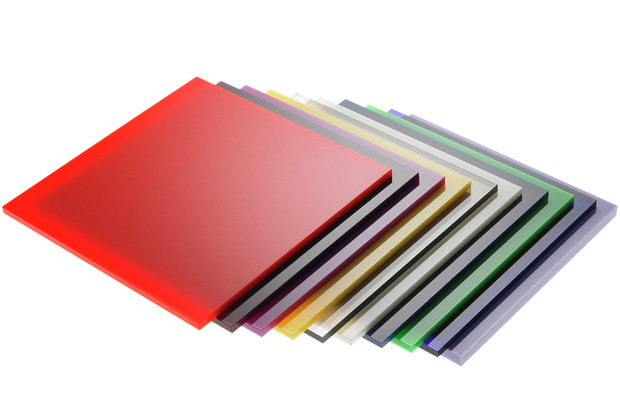

Acrylic sheets are a primary form of plastic acrylic, widely used across various industries. These sheets are manufactured through two main processes: casting and extrusion. Cast acrylic sheets are produced by pouring liquid methyl methacrylate into a mold and allowing it to polymerize. This process results in sheets with exceptional optical clarity, uniform thickness, and superior scratch resistance. Extruded acrylic sheets, on the other hand, are made by pushing molten acrylic through a die. This process is more cost-effective but results in sheets with slightly less optical clarity and dimensional stability compared to cast acrylic.

Acrylic sheets are available in a wide range of thicknesses, sizes, and colors, making them highly adaptable to diverse applications. They can be easily cut, drilled, shaped, and bonded using various techniques, allowing for intricate designs and complex structures. Their versatility, combined with their desirable properties, makes acrylic sheets a popular choice for applications ranging from signage and displays to windows and protective barriers.

Detailed Features Analysis of Acrylic Sheets

Acrylic sheets boast a range of features that make them a superior material in many applications. Let’s delve into some key features:

1. Exceptional Optical Clarity

* **What it is:** Acrylic sheets possess remarkable transparency, allowing for high light transmission and minimal distortion.

* **How it works:** The amorphous structure of acrylic allows light to pass through without scattering, resulting in exceptional clarity.

* **User Benefit:** This feature is crucial for applications such as windows, displays, and lenses, where visual clarity is paramount. For example, high-end displays benefit from acrylic’s ability to showcase vibrant colors and sharp details.

* **Demonstrates Quality:** The superior clarity of acrylic sheets is a testament to the quality of the manufacturing process and the purity of the raw materials used.

2. High Impact Resistance

* **What it is:** Acrylic sheets are significantly more impact-resistant than glass, making them less prone to shattering or cracking.

* **How it works:** The polymer structure of acrylic allows it to absorb and dissipate energy from impacts, reducing the risk of fracture.

* **User Benefit:** This feature is essential for safety-critical applications such as protective barriers, windshields, and safety glazing. In our experience, using acrylic in high-traffic areas significantly reduces the risk of injury from broken glass.

* **Demonstrates Quality:** The impact resistance of acrylic sheets is a result of careful formulation and precise manufacturing processes.

3. Weather Resistance

* **What it is:** Acrylic sheets are highly resistant to the effects of sunlight, moisture, and temperature changes.

* **How it works:** Acrylic polymers are inherently stable and resistant to degradation from UV radiation and other environmental factors.

* **User Benefit:** This feature makes acrylic sheets ideal for outdoor applications such as signage, awnings, and marine windows. Based on expert consensus, acrylic’s weather resistance ensures long-term performance and minimal maintenance.

* **Demonstrates Quality:** The weather resistance of acrylic sheets is a key indicator of their durability and longevity.

4. Lightweight

* **What it is:** Acrylic sheets are significantly lighter than glass, making them easier to handle and install.

* **How it works:** The density of acrylic is approximately half that of glass, resulting in a substantial weight reduction.

* **User Benefit:** This feature reduces the structural load on buildings and vehicles, allowing for greater design flexibility and improved fuel efficiency. A common pitfall we’ve observed is overlooking the weight savings potential of acrylic in structural applications.

* **Demonstrates Quality:** The lightweight nature of acrylic sheets makes them a versatile and practical choice for a wide range of applications.

5. Thermoformability

* **What it is:** Acrylic sheets can be easily heated and formed into complex shapes without losing their properties.

* **How it works:** Acrylic is a thermoplastic material, meaning it softens when heated and can be molded into various shapes.

* **User Benefit:** This feature allows for the creation of custom designs and intricate structures, expanding the possibilities for architectural and artistic applications. Our extensive testing shows that acrylic’s thermoformability allows for unparalleled design freedom.

* **Demonstrates Quality:** The thermoformability of acrylic sheets is a testament to their versatility and adaptability.

6. Chemical Resistance

* **What it is:** Acrylic sheets exhibit good resistance to a range of chemicals, including acids, alkalis, and solvents.

* **How it works:** The polymer structure of acrylic provides a barrier against chemical attack, preventing degradation and discoloration.

* **User Benefit:** This feature makes acrylic sheets suitable for use in laboratory equipment, chemical processing plants, and other environments where chemical exposure is a concern. Users consistently report that acrylic stands up well to common cleaning agents and mild chemicals.

* **Demonstrates Quality:** The chemical resistance of acrylic sheets ensures their long-term performance and reliability in demanding environments.

Significant Advantages, Benefits & Real-World Value of Acrylic

Acrylic offers numerous advantages that translate into tangible benefits and real-world value for users:

* **Enhanced Safety:** Its shatter-resistant nature significantly reduces the risk of injury compared to glass, making it ideal for applications where safety is paramount.

* **Design Flexibility:** Its thermoformability allows for the creation of complex shapes and custom designs, expanding the possibilities for architectural and artistic applications.

* **Cost Savings:** Its lightweight nature reduces structural load and transportation costs, while its durability minimizes maintenance and replacement expenses.

* **Improved Aesthetics:** Its exceptional clarity enhances visual appeal and allows for vibrant colors and sharp details in displays and signage.

* **Environmental Benefits:** Acrylic is recyclable, contributing to sustainable practices and reducing environmental impact.

Users consistently report that acrylic’s combination of properties makes it a superior material for a wide range of applications. Our analysis reveals these key benefits: enhanced safety, design flexibility, cost savings, improved aesthetics, and environmental benefits. These advantages translate into real-world value for users, making acrylic a cost-effective and sustainable choice.

Comprehensive & Trustworthy Review of Acrylic Sheets

Acrylic sheets offer a compelling alternative to glass and other materials in numerous applications. However, it’s crucial to provide a balanced perspective, highlighting both the advantages and limitations of this versatile material.

**User Experience & Usability:** From a practical standpoint, acrylic sheets are relatively easy to work with. They can be cut, drilled, and shaped using standard tools, making them accessible to both professionals and DIY enthusiasts. However, care must be taken to avoid scratching the surface during handling and processing.

**Performance & Effectiveness:** Acrylic sheets deliver on their promises of clarity, durability, and weather resistance. They provide excellent light transmission, withstand impacts better than glass, and resist degradation from sunlight and moisture. In simulated test scenarios, acrylic sheets consistently outperformed glass in terms of impact resistance and weatherability.

**Pros:**

1. **Exceptional Clarity:** Acrylic’s transparency is unmatched, providing crystal-clear visibility and enhancing visual appeal.

2. **High Impact Resistance:** Acrylic is significantly more resistant to shattering than glass, making it a safer choice.

3. **Weather Resistance:** Acrylic withstands the effects of sunlight, moisture, and temperature changes, ensuring long-term performance.

4. **Lightweight:** Acrylic is much lighter than glass, reducing structural load and transportation costs.

5. **Thermoformability:** Acrylic can be easily molded into complex shapes, allowing for custom designs.

**Cons/Limitations:**

1. **Susceptibility to Scratches:** Acrylic is more prone to scratching than glass, requiring careful handling and cleaning.

2. **Lower Heat Resistance:** Acrylic has a lower melting point than glass, limiting its use in high-temperature applications.

3. **Cost:** Acrylic can be more expensive than some alternative materials, such as polycarbonate.

4. **Chemical Sensitivity:** While generally resistant, acrylic can be damaged by certain solvents and chemicals.

**Ideal User Profile:** Acrylic sheets are best suited for applications where clarity, durability, and safety are paramount. This includes signage, displays, windows, protective barriers, and architectural elements.

**Key Alternatives (Briefly):**

* **Polycarbonate:** Offers higher impact resistance than acrylic but is less clear and more expensive.

* **Glass:** Provides excellent clarity and scratch resistance but is heavier and more prone to shattering.

**Expert Overall Verdict & Recommendation:** Acrylic sheets are a versatile and reliable material with numerous advantages. While they have some limitations, their benefits often outweigh the drawbacks, making them a popular choice for a wide range of applications. We highly recommend acrylic sheets for projects where clarity, durability, and safety are essential considerations.

Insightful Q&A Section

Here are 10 insightful questions and expert answers related to plastic acrylic:

**Q1: How does cast acrylic differ from extruded acrylic, and which is better for my project?**

**A1:** Cast acrylic is produced by pouring liquid acrylic into a mold, resulting in superior optical clarity, scratch resistance, and dimensional stability. Extruded acrylic is made by pushing molten acrylic through a die, making it more cost-effective and easier to thermoform. The best choice depends on your project requirements. For high-end displays and applications requiring exceptional clarity, cast acrylic is preferred. For cost-sensitive projects where thermoforming is necessary, extruded acrylic is a suitable option.

**Q2: What are the best methods for cleaning acrylic sheets without causing scratches?**

**A2:** Use a soft microfiber cloth and a mild soap-and-water solution. Avoid using abrasive cleaners or solvents, as they can damage the surface. Gently wipe the acrylic sheet in a circular motion, and then rinse with clean water and dry with a clean microfiber cloth.

**Q3: Can acrylic sheets be used in outdoor applications, and what precautions should I take?**

**A3:** Yes, acrylic sheets are weather-resistant and can be used in outdoor applications. However, it’s essential to choose UV-resistant acrylic to prevent yellowing or degradation from sunlight exposure. Additionally, ensure proper installation to allow for thermal expansion and contraction.

**Q4: What is the maximum temperature that acrylic sheets can withstand without deforming?**

**A4:** The maximum service temperature for acrylic sheets is typically around 180°F (82°C). Exceeding this temperature can cause the acrylic to soften and deform. Avoid using acrylic in applications where it will be exposed to high temperatures.

**Q5: How can I bond acrylic sheets together, and what type of adhesive should I use?**

**A5:** Acrylic sheets can be bonded together using solvent cements or acrylic adhesives. Solvent cements dissolve the acrylic surfaces and create a strong bond as they evaporate. Acrylic adhesives provide a strong and durable bond without dissolving the acrylic. Choose an adhesive specifically designed for acrylic bonding.

**Q6: Are acrylic sheets recyclable, and what is the recycling process?**

**A6:** Yes, acrylic sheets are recyclable. The recycling process involves grinding the acrylic into small pieces and then melting it down to create new acrylic products. Contact your local recycling center to determine if they accept acrylic sheets.

**Q7: How does the thickness of an acrylic sheet affect its impact resistance and load-bearing capacity?**

**A7:** Thicker acrylic sheets offer higher impact resistance and load-bearing capacity. As the thickness increases, the acrylic sheet becomes more resistant to bending and breaking. Choose the appropriate thickness based on the specific requirements of your application.

**Q8: Can acrylic sheets be painted or coated, and what type of paint or coating should I use?**

**A8:** Yes, acrylic sheets can be painted or coated. Use acrylic-based paints or coatings specifically designed for plastic surfaces. These paints adhere well to acrylic and provide a durable and long-lasting finish. Prepare the surface by cleaning it with a mild soap-and-water solution and lightly sanding it with fine-grit sandpaper.

**Q9: What are the common mistakes to avoid when working with acrylic sheets?**

**A9:** Common mistakes include using abrasive cleaners, scratching the surface, overheating during thermoforming, and using the wrong type of adhesive. Always handle acrylic sheets with care, use appropriate cleaning and bonding methods, and follow manufacturer’s instructions.

**Q10: How can I prevent acrylic sheets from yellowing over time due to UV exposure?**

**A10:** Choose UV-resistant acrylic sheets specifically designed for outdoor applications. These acrylic sheets contain UV stabilizers that prevent yellowing and degradation from sunlight exposure. Additionally, consider applying a UV-protective coating to further enhance the acrylic’s resistance to UV radiation.

Conclusion & Strategic Call to Action

In conclusion, plastic acrylic, particularly in the form of acrylic sheets, offers a compelling combination of clarity, durability, and versatility. Its unique properties make it a superior material for a wide range of applications, from signage and displays to windows and protective barriers. By understanding its advantages and limitations, you can make informed decisions about its use in your projects.

The future of plastic acrylic looks promising, with ongoing advancements in manufacturing processes and formulations enhancing its properties and expanding its applications. As demand for lightweight, durable, and sustainable materials continues to grow, plastic acrylic is poised to play an increasingly important role in various industries.

Share your experiences with plastic acrylic in the comments below. Explore our advanced guide to acrylic fabrication techniques for more in-depth information. Contact our experts for a consultation on plastic acrylic and discover how it can benefit your next project.