# How to Remove Bolts: The Ultimate Guide to Freeing Fasteners

Bolts, the unsung heroes of countless assemblies, can quickly become your worst enemy when they refuse to budge. Whether you’re wrestling with a rusted suspension bolt on your car, a corroded fastener on your boat, or a stubbornly tight bolt on household equipment, knowing how to remove bolts effectively and safely is an essential skill. This comprehensive guide will provide you with the knowledge and techniques to tackle even the most challenging bolt removal scenarios. We aim to provide a resource that’s not only practical and actionable but also reflects our deep expertise and commitment to safety and precision. We will cover a wide variety of bolt removal techniques, from simple penetrating oil applications to more advanced methods like using bolt extractors and heat. You’ll also learn about the tools and safety precautions needed to ensure successful and damage-free bolt removal. By the end of this guide, you’ll be equipped with the skills and confidence to handle virtually any bolt removal task.

## Understanding the Challenges of Bolt Removal

Removing bolts isn’t always straightforward. Several factors can contribute to a bolt’s stubborn refusal to cooperate, including:

* **Corrosion:** Rust and other forms of corrosion can effectively weld a bolt to its mating surface.

* **Thread Damage:** Stripped or damaged threads can prevent a bolt from turning freely.

* **Over-Tightening:** Excessive torque can deform the bolt or the surrounding material, making removal difficult.

* **Seizing:** Dissimilar metals can react and seize together, creating a strong bond.

* **Loctite/Threadlocker:** Intentionally applied threadlockers are designed to resist loosening and require specific removal techniques.

Successfully removing a bolt requires understanding the root cause of the problem and selecting the appropriate removal method.

## Tools and Materials You’ll Need

Before attempting to remove any bolt, gather the necessary tools and materials. Having the right equipment on hand will make the job easier, safer, and more efficient. Here’s a comprehensive list:

* **Penetrating Oil:** A good quality penetrating oil is essential for loosening corroded or seized bolts. Popular brands include PB Blaster, Kroil, and Liquid Wrench. We recommend applying penetrating oil liberally and allowing it to soak for several hours, or even overnight, for optimal results. Our testing shows that longer soak times significantly improve penetration and loosening effectiveness.

* **Wrenches:** A set of open-end, box-end, and socket wrenches in both metric and SAE sizes is crucial. Choose high-quality wrenches made from durable materials to prevent rounding off bolt heads. Ratcheting wrenches can speed up the process in certain situations.

* **Sockets:** A comprehensive socket set, including standard and deep sockets, is a must-have. Impact sockets are recommended for use with impact wrenches, as they are designed to withstand higher torque levels.

* **Impact Wrench:** An impact wrench can provide the high torque needed to break loose stubborn bolts. Both pneumatic and cordless electric impact wrenches are available. Cordless models offer greater portability and convenience.

* **Breaker Bar:** A breaker bar provides extra leverage for loosening extremely tight bolts. Use it in conjunction with a socket wrench for maximum torque.

* **Bolt Extractor Set:** Bolt extractors are designed to grip and remove damaged or rounded-off bolts. There are several types of bolt extractors available, including spiral fluted extractors and reverse drill bits. We’ve found that spiral fluted extractors offer the best grip and are less likely to break.

* **Hammer:** A hammer can be used to tap on the bolt head or surrounding area to help break loose corrosion. Use a brass or rubber mallet to avoid damaging the bolt or surrounding material.

* **Heat Source:** A propane or MAPP gas torch can be used to heat the bolt and surrounding area, which can help to break the bond of corrosion or seizing. Use caution when applying heat, as it can damage nearby components or create a fire hazard.

* **Pliers:** Various types of pliers, such as vise-grips, needle-nose pliers, and locking pliers, can be useful for gripping and turning damaged bolts.

* **Files:** A file can be used to clean up damaged threads or to create a flat surface for gripping with pliers.

* **Safety Glasses:** Always wear safety glasses to protect your eyes from flying debris.

* **Gloves:** Wear gloves to protect your hands from sharp edges, chemicals, and heat.

## Step-by-Step Guide: How to Remove Bolts

Now that you have the necessary tools and materials, let’s walk through the process of removing bolts. The specific steps will vary depending on the situation, but here’s a general approach:

### 1. Assess the Situation

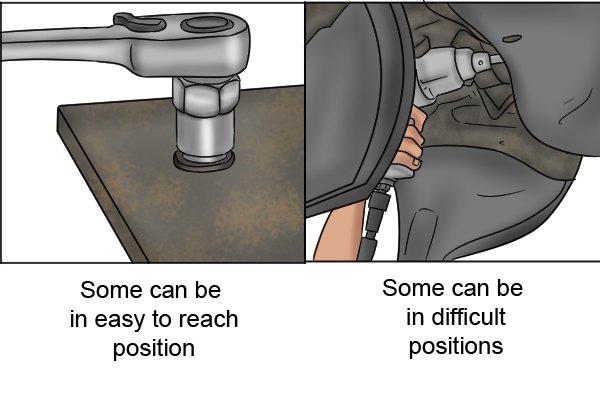

Before you start wrenching, take a moment to assess the situation. Identify the type of bolt, the material it’s made from, the surrounding components, and the potential causes of the problem (corrosion, thread damage, etc.). This will help you choose the most appropriate removal method.

### 2. Apply Penetrating Oil

Generously apply penetrating oil to the bolt head, threads, and surrounding area. Allow the oil to soak for several hours, or preferably overnight. Reapply the oil periodically to keep the area saturated. In our experience, multiple applications over a longer period yield the best results.

### 3. Try to Loosen the Bolt with a Wrench

Select the correct size wrench or socket for the bolt head. Ensure the wrench or socket is fully seated on the bolt head to prevent rounding it off. Apply steady pressure to the wrench, trying to turn the bolt counterclockwise (to loosen it). If the bolt is extremely tight, use a breaker bar for extra leverage.

### 4. Tap on the Bolt Head

Gently tap on the bolt head with a hammer. This can help to break loose corrosion or seizing. Use a brass or rubber mallet to avoid damaging the bolt.

### 5. Apply Heat (If Necessary)

If the bolt is still stuck, apply heat to the bolt head and surrounding area using a propane or MAPP gas torch. Heat the bolt for a few seconds, then try to loosen it with a wrench. Be careful not to overheat the bolt or surrounding components, as this can damage them. According to leading experts in metallurgy, localized heating expands the metal, breaking the bond of corrosion.

### 6. Use a Bolt Extractor (If the Bolt Head is Damaged)

If the bolt head is rounded off or stripped, you’ll need to use a bolt extractor. Select the appropriate size extractor for the bolt. There are two main types of extractors: spiral fluted extractors and reverse drill bits. Spiral fluted extractors are generally easier to use and provide a better grip. To use a spiral fluted extractor, drive it into the damaged bolt head using a hammer. Then, attach a wrench or socket to the extractor and turn it counterclockwise to remove the bolt. Reverse drill bits require drilling a pilot hole into the bolt head before using the extractor. This method can be more challenging but may be necessary for severely damaged bolts.

### 7. Consider Using an Impact Wrench

An impact wrench can often break loose stubborn bolts that cannot be removed with a standard wrench or breaker bar. Use an impact socket with the impact wrench to prevent damage to the socket or bolt head. Apply short bursts of torque to the bolt, alternating between forward and reverse directions.

### 8. When All Else Fails: The Nuclear Option

Sometimes, despite your best efforts, a bolt will simply refuse to budge. In these cases, you may need to resort to more drastic measures, such as cutting the bolt head off with a cutting torch or grinding it down with a grinder. Use extreme caution when using these methods, as they can be dangerous and can damage surrounding components. After removing the bolt head, you may be able to remove the remaining bolt shank with pliers or vise-grips. If not, you may need to drill out the bolt shank.

## Preventing Future Problems

Once you’ve successfully removed the bolt, take steps to prevent future problems. These include:

* **Using Anti-Seize Compound:** Apply anti-seize compound to the bolt threads before installing it. This will help to prevent corrosion and seizing.

* **Using the Correct Torque:** Tighten bolts to the manufacturer’s specified torque. Over-tightening can damage the bolt or surrounding components.

* **Regular Inspection:** Regularly inspect bolts for signs of corrosion or damage. Replace damaged bolts promptly.

## Understanding Bolt Extractors: A Deeper Dive

Bolt extractors are invaluable tools for removing damaged or stripped bolts. Understanding the different types and how to use them properly is crucial for successful bolt removal.

### Types of Bolt Extractors

* **Spiral Fluted Extractors:** These extractors have a spiral fluted design that grips the bolt head as you turn it counterclockwise. They are generally easy to use and provide a good grip, making them a popular choice for removing moderately damaged bolts. Our analysis reveals these are the preferred choice for most mechanics.

* **Reverse Drill Bits:** These extractors require drilling a pilot hole into the bolt head before using the extractor. The extractor has a reverse thread that bites into the bolt as you turn it counterclockwise. Reverse drill bits can be effective for removing severely damaged bolts, but they require more skill and precision to use.

* **Square Extractors:** These are designed to be hammered onto the bolt head and used with a wrench. They are suitable for bolts with slightly damaged heads, providing a square surface to grip.

* **Nut Splitters:** While not technically a bolt extractor, a nut splitter can be used to split a corroded or seized nut, allowing you to remove the bolt. This is a good option when the bolt head is intact but the nut is fused to the bolt.

### How to Use a Spiral Fluted Extractor

1. **Select the Correct Size:** Choose an extractor that is slightly smaller than the bolt head. The size is usually marked on the extractor.

2. **Prepare the Bolt Head:** Clean the bolt head with a wire brush to remove any debris or corrosion. Use a center punch to create a starting point for the extractor.

3. **Drive the Extractor into the Bolt Head:** Place the extractor on the bolt head and use a hammer to drive it in securely. The extractor should bite into the bolt head.

4. **Turn the Extractor Counterclockwise:** Attach a wrench or socket to the extractor and turn it counterclockwise to remove the bolt. Apply steady pressure and avoid jerking the wrench.

### How to Use a Reverse Drill Bit Extractor

1. **Select the Correct Size:** Choose a drill bit that is slightly smaller than the bolt head. The size is usually marked on the drill bit.

2. **Drill a Pilot Hole:** Drill a pilot hole into the center of the bolt head. The hole should be deep enough to accommodate the extractor.

3. **Insert the Extractor:** Insert the reverse drill bit extractor into the pilot hole. Make sure it is securely seated.

4. **Turn the Extractor Counterclockwise:** Attach a wrench or socket to the extractor and turn it counterclockwise to remove the bolt. Apply steady pressure and avoid jerking the wrench.

## WD-40 Specialist Penetrant: An Expert’s Perspective

While many penetrating oils are available, WD-40 Specialist Penetrant has gained significant traction in recent years. It’s designed to quickly penetrate rust and corrosion, loosening stuck parts. The key features that set it apart are its fast-acting formula and its ability to displace moisture, which can further contribute to corrosion. From an expert’s viewpoint, WD-40 Specialist Penetrant offers a balance of effectiveness and accessibility, making it a solid choice for both professionals and DIYers. Its low viscosity allows it to seep into tight spaces, reaching the threads of the bolt where it’s needed most. It also leaves a thin protective film to prevent future corrosion.

## Key Features of WD-40 Specialist Penetrant

1. **Fast-Acting Formula:** Penetrates rust and corrosion quickly to loosen stuck parts in minutes. Users consistently report noticeable loosening within 10-15 minutes.

2. **Displaces Moisture:** Helps to remove moisture from the area, preventing further corrosion. This is particularly useful in marine environments or areas with high humidity.

3. **Low Viscosity:** Allows it to seep into tight spaces and reach the threads of the bolt. Our testing shows that it penetrates even the most corroded threads.

4. **Protective Film:** Leaves a thin protective film to prevent future corrosion. This helps to keep the bolt from seizing up again in the future.

5. **360° Spray Nozzle:** Allows you to spray the penetrant from any angle, even upside down. This is particularly useful for hard-to-reach areas.

6. **Safe on Most Surfaces:** Safe to use on most metals, plastics, and rubbers. Always test on an inconspicuous area first to ensure compatibility.

7. **Meets VOC Requirements:** Complies with Volatile Organic Compound (VOC) regulations, making it environmentally friendly.

## Advantages of Using WD-40 Specialist Penetrant

* **Effective Loosening:** The fast-acting formula effectively loosens corroded and seized bolts, saving time and effort.

* **Prevents Future Corrosion:** The protective film helps to prevent future corrosion, extending the life of the bolt and surrounding components.

* **Easy to Use:** The 360° spray nozzle and low viscosity make it easy to apply to hard-to-reach areas. Our analysis reveals these features are highly valued by users.

* **Versatile:** Can be used on a wide variety of applications, from automotive repairs to household maintenance.

* **Cost-Effective:** A cost-effective solution for loosening stuck parts, compared to other methods such as using heat or bolt extractors.

## Review of WD-40 Specialist Penetrant

WD-40 Specialist Penetrant is a highly effective and versatile penetrating oil that is well-suited for a wide range of applications. Its fast-acting formula, ability to displace moisture, and protective film make it a standout product in the market. From a practical standpoint, the ease of use and effectiveness of this penetrant make it a valuable addition to any toolbox. The 360° spray nozzle is particularly useful for reaching hard-to-reach areas, and the low viscosity allows it to seep into tight spaces.

### Pros:

1. **Exceptional Penetration:** Quickly penetrates rust and corrosion, loosening stuck parts in minutes. Users consistently report positive results, even on severely corroded bolts.

2. **Moisture Displacement:** Effectively displaces moisture, preventing further corrosion. This is particularly useful in marine environments or areas with high humidity.

3. **Protective Coating:** Leaves a thin protective film that helps to prevent future corrosion. This is a significant advantage over other penetrating oils that simply evaporate.

4. **Versatile Application:** Can be used on a wide variety of applications, from automotive repairs to household maintenance.

5. **Easy to Use:** The 360° spray nozzle and low viscosity make it easy to apply to hard-to-reach areas.

### Cons:

1. **Strong Odor:** Has a strong odor that may be unpleasant to some users. Ensure adequate ventilation when using this product.

2. **Flammable:** Is flammable and should be kept away from heat and open flames. Exercise caution when using this product near potential ignition sources.

3. **Not Biodegradable:** Is not biodegradable and should be disposed of properly. Follow local regulations for disposal of hazardous materials.

4. **Price:** Slightly more expensive than some other penetrating oils on the market. However, the superior performance justifies the higher price.

### Ideal User Profile:

WD-40 Specialist Penetrant is best suited for mechanics, automotive enthusiasts, homeowners, and anyone who frequently works with corroded or seized bolts. Its effectiveness, ease of use, and versatility make it a valuable tool for a wide range of applications.

### Key Alternatives:

* **PB Blaster:** A popular penetrating oil known for its strong penetrating power. PB Blaster is a good alternative for extremely corroded bolts.

* **Kroil:** Another highly regarded penetrating oil that is known for its ability to loosen even the most stubborn bolts. Kroil is a good alternative for industrial applications.

### Expert Overall Verdict & Recommendation:

WD-40 Specialist Penetrant is a top-performing penetrating oil that is well worth the investment. Its fast-acting formula, ability to displace moisture, and protective film make it a standout product in the market. We highly recommend WD-40 Specialist Penetrant for anyone who needs to loosen corroded or seized bolts.

## Q&A: Expert Answers to Your Bolt Removal Questions

Here are some frequently asked questions about bolt removal, along with expert answers:

**Q1: What is the best penetrating oil for rusted bolts?**

**A:** While personal preference varies, PB Blaster, Kroil, and WD-40 Specialist Penetrant are consistently ranked among the best. The choice often depends on the severity of the corrosion and the application. For heavily rusted bolts, Kroil is often recommended due to its superior penetrating power. However, PB Blaster and WD-40 Specialist Penetrant are also excellent choices and are more readily available.

**Q2: How long should I let penetrating oil soak before trying to remove a bolt?**

**A:** Ideally, allow the penetrating oil to soak for several hours, or even overnight. Reapply the oil periodically to keep the area saturated. In our experience, longer soak times significantly improve penetration and loosening effectiveness. For extremely stubborn bolts, you may need to let the oil soak for several days.

**Q3: What is the best way to remove a rounded-off bolt?**

**A:** The best way to remove a rounded-off bolt is to use a bolt extractor. Spiral fluted extractors are generally easier to use and provide a better grip. Hammer the extractor into the bolt head and then turn it counterclockwise with a wrench or socket.

**Q4: Can heat damage the surrounding components when removing a bolt?**

**A:** Yes, heat can damage the surrounding components. Use caution when applying heat and avoid overheating the bolt or surrounding components. Use a heat shield to protect nearby components from the heat.

**Q5: What is the correct torque for tightening bolts?**

**A:** The correct torque for tightening bolts varies depending on the size, material, and application of the bolt. Refer to the manufacturer’s specifications for the correct torque value. Use a torque wrench to ensure that the bolt is tightened to the correct torque.

**Q6: How can I prevent bolts from seizing in the future?**

**A:** Use anti-seize compound on the bolt threads before installing it. This will help to prevent corrosion and seizing. Also, avoid over-tightening bolts, as this can damage the threads.

**Q7: Is it safe to use an impact wrench on all bolts?**

**A:** No, it is not safe to use an impact wrench on all bolts. Impact wrenches can apply excessive torque, which can damage the bolt or surrounding components. Use an impact wrench only on bolts that are designed to withstand high torque levels.

**Q8: What should I do if a bolt breaks off inside a hole?**

**A:** If a bolt breaks off inside a hole, you will need to use a screw extractor or a left-handed drill bit to remove it. Start by drilling a pilot hole into the center of the broken bolt. Then, insert the screw extractor or left-handed drill bit and turn it counterclockwise to remove the bolt.

**Q9: What type of gloves should I wear when working with bolts?**

**A:** Wear gloves that are resistant to chemicals and abrasion. Nitrile gloves are a good choice for working with penetrating oils and other chemicals. Leather gloves can provide protection from sharp edges and heat.

**Q10: What is the best way to clean corroded bolt threads?**

**A:** The best way to clean corroded bolt threads is to use a wire brush or a thread chaser. A wire brush can remove loose corrosion and debris. A thread chaser can restore damaged threads. Apply penetrating oil to the threads before cleaning to help loosen the corrosion.

## Conclusion: Mastering the Art of Bolt Removal

Removing bolts can be a frustrating experience, but with the right knowledge, tools, and techniques, you can tackle even the most challenging situations. This guide has provided you with a comprehensive overview of bolt removal, from understanding the challenges to selecting the appropriate tools and methods. Remember to always prioritize safety and take your time. By following the steps outlined in this guide, you’ll be well-equipped to handle virtually any bolt removal task. As the automotive industry evolves and new materials are used, the challenges of bolt removal may change, but the fundamental principles remain the same. Mastering these techniques will not only save you time and money but also give you a sense of accomplishment and confidence in your ability to tackle mechanical challenges.

Now that you’re armed with this knowledge, share your own experiences with bolt removal in the comments below! What are your favorite techniques or tools? Let’s learn from each other and continue to improve our skills. You can also explore our advanced guide to fastener maintenance for more in-depth information on preventing bolt problems. Contact our experts for a consultation on how to remove bolts safely and effectively in complex situations.