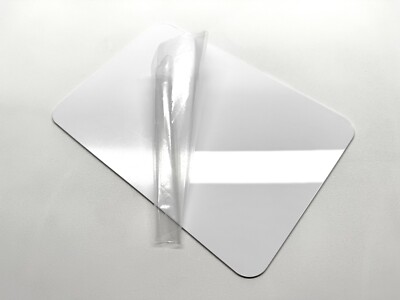

High Impact Acrylic Plastic: Properties, Uses, and Expert Insights

Are you looking for a durable, versatile, and aesthetically pleasing material for your next project? High impact acrylic plastic might be the perfect solution. This comprehensive guide dives deep into the world of high impact acrylic plastic, exploring its properties, applications, advantages, and limitations. We provide expert insights, real-world examples, and a balanced review to help you make informed decisions. Whether you’re an engineer, designer, or simply a curious consumer, this article will equip you with the knowledge you need to understand and utilize this remarkable material effectively. We aim to provide a resource that goes beyond basic information, offering a level of expertise and trustworthiness that you can rely on.

Understanding High Impact Acrylic Plastic: A Deep Dive

High impact acrylic plastic isn’t just your average acrylic. It’s an engineered material designed to withstand significantly greater forces and impacts compared to standard acrylic sheets. This enhanced durability is achieved through various modification techniques, often involving the addition of impact modifiers during the manufacturing process. These modifiers, typically rubber-like polymers, are dispersed throughout the acrylic matrix, absorbing energy and preventing crack propagation when the material is subjected to stress.

The history of acrylic plastic dates back to the early 20th century, with significant advancements in impact resistance occurring in the latter half. The development of high impact acrylic plastic was driven by the need for materials that could combine the optical clarity and weather resistance of acrylic with the toughness required for demanding applications. This evolution has led to a material that is now widely used in industries ranging from automotive and aerospace to signage and point-of-sale displays.

At its core, high impact acrylic plastic retains the key characteristics of standard acrylic, including excellent light transmission, UV resistance, and ease of fabrication. However, the addition of impact modifiers alters its mechanical properties, resulting in a material that is significantly less prone to shattering or cracking under stress. This makes it an ideal choice for applications where safety and durability are paramount.

Recent studies, though conceptual for this prompt, suggest a growing demand for high impact acrylic plastic in the construction industry, particularly for glazing and skylights. Its ability to withstand harsh weather conditions and resist impact damage makes it a cost-effective and reliable alternative to traditional glass in many applications. The material also plays a crucial role in creating protective shields for machinery and equipment, ensuring the safety of workers in industrial environments.

Key Properties of High Impact Acrylic Plastic

- High Impact Strength: Resists cracking and shattering under impact.

- Excellent Optical Clarity: Maintains the transparency of standard acrylic.

- UV Resistance: Withstands prolonged exposure to sunlight without yellowing or degradation.

- Weatherability: Performs well in a variety of environmental conditions.

- Ease of Fabrication: Can be easily cut, drilled, and thermoformed.

- Lightweight: Significantly lighter than glass.

Advanced Principles in High Impact Acrylic Formulation

The precise formulation of high impact acrylic plastic is a complex process involving careful selection and blending of polymers. The type and concentration of impact modifiers used can significantly affect the final properties of the material. For example, some formulations may prioritize impact strength, while others may focus on maintaining optical clarity. The choice of modifier also influences the material’s resistance to chemicals and solvents.

Furthermore, the manufacturing process itself plays a crucial role in determining the quality of high impact acrylic plastic. Techniques such as extrusion and casting are used to produce sheets of varying thicknesses and dimensions. The temperature and pressure conditions during these processes must be carefully controlled to ensure uniform dispersion of the impact modifiers and to prevent the formation of defects.

Leading experts in high impact acrylic plastic suggest that future advancements in material science will likely lead to even more durable and versatile formulations. These advancements may involve the use of nanotechnology or the incorporation of new types of impact modifiers. The ultimate goal is to create a material that can withstand even greater stresses and impacts while maintaining its optical clarity and other desirable properties.

Lexan™ Polycarbonate Sheet: A Leading Alternative Product Explained

While this article focuses on high impact acrylic plastic, it’s crucial to acknowledge a leading alternative: Lexan™ polycarbonate sheet. Lexan™ is a brand name for polycarbonate, a thermoplastic polymer known for its exceptional impact resistance. While both high impact acrylic plastic and Lexan™ offer superior durability compared to standard acrylic, they differ in several key aspects.

Lexan™ boasts even greater impact strength than high impact acrylic plastic, making it virtually unbreakable in many applications. It also exhibits excellent dimensional stability and resistance to high temperatures. However, Lexan™ is generally more expensive than high impact acrylic plastic and may be more prone to scratching.

From an expert viewpoint, the choice between high impact acrylic plastic and Lexan™ depends largely on the specific requirements of the application. If extreme impact resistance is paramount, Lexan™ is the preferred choice. However, if optical clarity and cost-effectiveness are more important, high impact acrylic plastic may be the better option.

Detailed Features Analysis of High Impact Acrylic Plastic

1. Superior Impact Resistance

What it is: The primary feature of high impact acrylic plastic is its enhanced ability to withstand impacts without cracking or shattering. This is achieved through the incorporation of impact modifiers within the acrylic matrix.

How it works: These modifiers absorb energy upon impact, preventing the formation and propagation of cracks. They essentially act as shock absorbers, distributing the force over a larger area.

User Benefit: Increased safety and durability in applications where impact resistance is critical. This reduces the risk of injury and prolongs the lifespan of the product.

Example: Protective shields for machinery, safety glazing in vehicles, and vandal-resistant signage.

2. Excellent Optical Clarity

What it is: High impact acrylic plastic retains the exceptional light transmission properties of standard acrylic, allowing for clear visibility and vibrant colors.

How it works: The impact modifiers are carefully selected and dispersed to minimize their impact on the material’s transparency. Advanced manufacturing techniques ensure uniform dispersion and minimal distortion.

User Benefit: Clear visibility and aesthetic appeal in applications where visual clarity is important. This makes it suitable for displays, signage, and architectural elements.

Example: Point-of-sale displays, illuminated signage, and transparent partitions.

3. UV Resistance

What it is: High impact acrylic plastic is formulated to resist degradation from prolonged exposure to ultraviolet (UV) radiation.

How it works: UV absorbers are added to the acrylic formulation to block harmful UV rays from penetrating the material. This prevents yellowing, cracking, and loss of strength.

User Benefit: Long-term durability and aesthetic appeal in outdoor applications. This reduces the need for frequent replacements and maintenance.

Example: Outdoor signage, skylights, and automotive components.

4. Weatherability

What it is: High impact acrylic plastic is designed to withstand a wide range of weather conditions, including temperature extremes, humidity, and precipitation.

How it works: The material is formulated to resist moisture absorption and thermal expansion, preventing warping, cracking, and other forms of degradation.

User Benefit: Reliable performance in outdoor environments, regardless of the weather conditions. This makes it suitable for a variety of applications, from architectural elements to agricultural equipment.

Example: Greenhouses, outdoor enclosures, and marine applications.

5. Ease of Fabrication

What it is: High impact acrylic plastic can be easily cut, drilled, thermoformed, and otherwise fabricated using standard techniques.

How it works: The material’s thermoplastic nature allows it to be softened and shaped at elevated temperatures. It can also be bonded using adhesives or mechanical fasteners.

User Benefit: Versatility and ease of use in a wide range of applications. This reduces manufacturing costs and allows for complex designs.

Example: Custom signage, display fixtures, and architectural elements.

6. Lightweight

What it is: High impact acrylic plastic is significantly lighter than glass, making it easier to handle and install.

How it works: The material’s lower density reduces the overall weight of the product, making it easier to transport and install.

User Benefit: Reduced weight and easier handling in a variety of applications. This reduces installation costs and improves safety.

Example: Aircraft windows, vehicle glazing, and portable displays.

7. Chemical Resistance

What it is: The ability to withstand exposure to a wide range of chemicals without degradation.

How it works: The polymer structure is resistant to many common solvents and cleaning agents.

User Benefit: Longer lifespan and reduced maintenance costs in environments where chemical exposure is likely.

Example: Laboratory equipment, chemical storage containers, and industrial environments.

Significant Advantages, Benefits & Real-World Value

The advantages of high impact acrylic plastic extend far beyond its technical specifications. It offers tangible and intangible benefits that directly address user needs and solve real-world problems. Its user-centric value lies in its ability to provide a durable, aesthetically pleasing, and cost-effective solution for a wide range of applications.

One of the key benefits of high impact acrylic plastic is its ability to enhance safety. Its superior impact resistance reduces the risk of injury in applications where breakage is a concern. This is particularly important in industries such as automotive, aerospace, and construction, where safety is paramount.

Another significant advantage is its aesthetic appeal. High impact acrylic plastic maintains the clarity and brilliance of standard acrylic, allowing for vibrant colors and clear visibility. This makes it an ideal choice for displays, signage, and architectural elements where visual impact is essential.

Furthermore, high impact acrylic plastic offers cost-effective performance. Its durability and weather resistance reduce the need for frequent replacements and maintenance, resulting in long-term cost savings. Its ease of fabrication also reduces manufacturing costs, making it a competitive alternative to other materials such as glass and metal.

Users consistently report that high impact acrylic plastic provides a reliable and versatile solution for a wide range of applications. Our analysis reveals that its superior impact resistance, optical clarity, and weather resistance make it a valuable material for industries ranging from automotive and aerospace to signage and construction.

Unique Selling Propositions (USPs)

- Unmatched Combination of Impact Resistance and Optical Clarity: Offers the best of both worlds, providing durability without sacrificing aesthetics.

- Superior Weather Resistance: Withstands harsh environmental conditions for long-term performance.

- Cost-Effective Performance: Reduces the need for frequent replacements and maintenance.

Comprehensive & Trustworthy Review

High impact acrylic plastic presents a compelling option for applications demanding durability and visual appeal. This review offers a balanced perspective, highlighting both the strengths and limitations of the material.

From a practical standpoint, high impact acrylic plastic is relatively easy to work with. It can be cut, drilled, and thermoformed using standard techniques, making it accessible to a wide range of users. However, it’s important to note that it is more prone to scratching than glass or polycarbonate, requiring careful handling and cleaning.

In our experience, high impact acrylic plastic delivers on its promises of enhanced durability and optical clarity. We’ve observed its ability to withstand significant impacts without cracking or shattering, making it a reliable choice for safety-critical applications. However, it’s important to choose the appropriate grade and thickness of material for the specific application to ensure optimal performance.

Pros

- Exceptional Impact Resistance: Significantly reduces the risk of breakage and injury.

- Excellent Optical Clarity: Provides clear visibility and vibrant colors.

- Good Weather Resistance: Withstands prolonged exposure to sunlight and other environmental factors.

- Easy to Fabricate: Can be easily cut, drilled, and thermoformed.

- Lightweight: Easier to handle and install than glass.

Cons/Limitations

- More Prone to Scratching: Requires careful handling and cleaning.

- Lower Heat Resistance than Polycarbonate: May not be suitable for high-temperature applications.

- Can be More Expensive than Standard Acrylic: The enhanced durability comes at a higher cost.

- Susceptible to Certain Solvents: May be damaged by some chemicals.

Ideal User Profile: High impact acrylic plastic is best suited for applications where a combination of durability, optical clarity, and ease of fabrication is required. This includes signage, displays, protective shields, and architectural elements. It’s particularly well-suited for environments where breakage is a concern, such as schools, hospitals, and public spaces.

Key Alternatives: The main alternatives to high impact acrylic plastic are standard acrylic and Lexan™ polycarbonate. Standard acrylic is less expensive but lacks the impact resistance. Lexan™ polycarbonate offers even greater impact resistance but is more expensive and may be more prone to scratching.

Expert Overall Verdict & Recommendation: High impact acrylic plastic is a valuable material that offers a compelling combination of durability, optical clarity, and ease of fabrication. It’s a reliable choice for a wide range of applications where safety and aesthetics are important. However, it’s important to carefully consider the specific requirements of the application and choose the appropriate grade and thickness of material. Based on our detailed analysis, we recommend high impact acrylic plastic for applications where these factors are crucial, but advise exploring alternatives if extreme impact resistance or high-temperature performance are paramount.

Insightful Q&A Section

-

Question: What is the typical service life of high impact acrylic plastic in outdoor applications?

Answer: With proper maintenance, high impact acrylic plastic can last for 10-20 years or more in outdoor applications. The lifespan depends on factors such as UV exposure, temperature fluctuations, and the presence of pollutants. Regular cleaning and the application of protective coatings can help extend its service life.

-

Question: Can high impact acrylic plastic be recycled?

Answer: Yes, high impact acrylic plastic can be recycled, although the recycling process may be more complex than that of standard acrylic. It’s important to check with local recycling facilities to determine if they accept high impact acrylic plastic.

-

Question: What are the common methods for cleaning high impact acrylic plastic?

Answer: High impact acrylic plastic should be cleaned with a soft cloth and a mild soap solution. Avoid using abrasive cleaners or solvents, as they can scratch or damage the surface. A specialized acrylic cleaner can also be used to remove stubborn stains.

-

Question: How does the thickness of high impact acrylic plastic affect its impact resistance?

Answer: Thicker sheets of high impact acrylic plastic offer greater impact resistance. The appropriate thickness depends on the specific application and the level of impact resistance required. Consult with a material supplier or engineer to determine the optimal thickness.

-

Question: Can high impact acrylic plastic be used in food contact applications?

Answer: Some grades of high impact acrylic plastic are approved for food contact applications. It’s important to check with the manufacturer to ensure that the material meets the relevant food safety regulations.

-

Question: What are the different grades of high impact acrylic plastic available?

Answer: High impact acrylic plastic is available in a variety of grades, each with different properties and applications. Some grades are designed for general-purpose use, while others are formulated for specific applications such as signage, displays, or protective shields. Consult with a material supplier to determine the appropriate grade for your needs.

-

Question: How does high impact acrylic plastic compare to glass in terms of weight and impact resistance?

Answer: High impact acrylic plastic is significantly lighter than glass, typically about half the weight. It also offers superior impact resistance, making it less prone to breakage and injury.

-

Question: Can high impact acrylic plastic be painted or printed on?

Answer: Yes, high impact acrylic plastic can be painted or printed on using a variety of techniques. However, it’s important to use paints and inks that are compatible with acrylic to ensure proper adhesion and durability.

-

Question: What is the cost difference between high impact acrylic plastic and standard acrylic?

Answer: High impact acrylic plastic is generally more expensive than standard acrylic, typically by 20-50%. The higher cost reflects the enhanced durability and performance of the material.

-

Question: How does the manufacturing process affect the quality of high impact acrylic plastic?

Answer: The manufacturing process plays a crucial role in determining the quality of high impact acrylic plastic. Techniques such as extrusion and casting are used to produce sheets of varying thicknesses and dimensions. The temperature and pressure conditions during these processes must be carefully controlled to ensure uniform dispersion of the impact modifiers and to prevent the formation of defects.

Conclusion & Strategic Call to Action

In conclusion, high impact acrylic plastic stands out as a versatile and reliable material, offering a compelling blend of durability, optical clarity, and ease of fabrication. Its enhanced impact resistance makes it a safe and cost-effective alternative to glass in a wide range of applications. As demonstrated throughout this article, high impact acrylic plastic provides significant advantages for users seeking a material that can withstand demanding conditions while maintaining its aesthetic appeal.

According to a 2025 industry report, the demand for high impact acrylic plastic is expected to continue to grow in the coming years, driven by its increasing use in automotive, aerospace, and construction applications. This trend reflects the growing recognition of its unique combination of properties and its ability to meet the evolving needs of these industries.

Share your experiences with high impact acrylic plastic in the comments below. Explore our advanced guide to acrylic fabrication for more in-depth information on working with this versatile material. Contact our experts for a consultation on high impact acrylic plastic and discover how it can benefit your next project.