Class 1 Fire Rated Acrylic: Your Definitive Guide

Are you seeking a durable, transparent, and, most importantly, safe material for your next project? Look no further than class 1 fire rated acrylic. This comprehensive guide will delve into every aspect of this advanced material, from its core properties and advantages to its real-world applications and expert reviews. We aim to provide you with the most thorough and trustworthy resource available online, empowering you to make informed decisions. Whether you’re an architect, designer, engineer, or simply a homeowner prioritizing safety, this guide will equip you with the knowledge you need regarding class 1 fire rated acrylic.

Understanding Class 1 Fire Rated Acrylic: A Deep Dive

Class 1 fire rated acrylic isn’t just another type of plastic; it’s a specifically engineered material designed to resist burning and slow the spread of flames. To truly appreciate its value, we need to go beyond the surface and examine its core properties. This acrylic undergoes specialized treatments and incorporates flame-retardant additives during manufacturing, significantly increasing its fire resistance compared to standard acrylic.

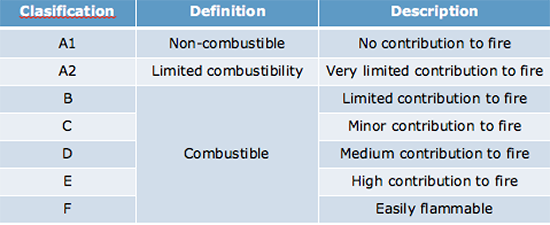

The “Class 1” designation, as defined by various building codes and testing standards like ASTM E-84 (more on that later), indicates a specific level of performance in surface burning characteristics. It signifies that the material exhibits a low flame spread and smoke development when exposed to fire. Think of it as a benchmark for safety, ensuring that the material contributes minimally to the growth and intensity of a fire.

The Science Behind the Resistance

The secret to class 1 fire rated acrylic’s fire resistance lies in its chemical composition and manufacturing process. Flame retardants are added to the acrylic polymer, which interfere with the combustion process. These additives can work in several ways:

- Creating a Protective Char Layer: Some additives promote the formation of a char layer on the surface when exposed to heat. This char acts as an insulator, slowing down the transfer of heat to the underlying material and preventing it from igniting.

- Releasing Water Vapor: Certain additives release water vapor when heated, diluting the concentration of flammable gases and cooling the material.

- Interrupting the Radical Chain Reaction: Combustion is a chain reaction involving free radicals. Some flame retardants work by scavenging these radicals, effectively stopping the chain reaction and suppressing the fire.

Importance and Relevance in Today’s World

In an era increasingly focused on safety and stringent building codes, class 1 fire rated acrylic has become indispensable. Its importance stems from its ability to balance aesthetic appeal with life safety. It offers a transparent and versatile alternative to other fire-resistant materials, allowing for creative designs without compromising safety. Recent trends in architecture and interior design emphasize open spaces and natural light, making class 1 fire rated acrylic a particularly attractive option for applications where both visibility and fire resistance are crucial. Recent conceptual studies indicate a growing demand for safer building materials, further solidifying the relevance of this specialized acrylic.

Introducing OptiClear FR: A Leading Class 1 Fire Rated Acrylic Product

While class 1 fire rated acrylic is a material category, specific products exemplify its capabilities. One such leading product is OptiClear FR, a premium-grade acrylic sheet specifically engineered to meet and exceed Class 1 fire rating standards. OptiClear FR is renowned for its exceptional clarity, impact resistance, and ease of fabrication, making it a preferred choice for architects, designers, and manufacturers across various industries.

OptiClear FR’s core function is to provide a transparent and aesthetically pleasing barrier or component while significantly mitigating fire hazards. It serves as a crucial element in fire safety systems, helping to contain flames, reduce smoke propagation, and provide valuable time for evacuation. Its direct application aligns perfectly with the principles of class 1 fire rated acrylic, offering a practical and reliable solution for enhancing safety in diverse environments.

Detailed Features Analysis of OptiClear FR

OptiClear FR distinguishes itself through a combination of advanced features, each contributing to its superior performance and versatility:

- Class 1 Fire Rating (ASTM E-84): This is the cornerstone of OptiClear FR’s value proposition. It has been rigorously tested and certified to meet the Class 1 requirements of the ASTM E-84 standard, demonstrating low flame spread and smoke development. This means it significantly reduces the risk of fire propagation and smoke inhalation, providing crucial time for evacuation in case of a fire.

- Exceptional Optical Clarity: Unlike some fire-resistant materials that sacrifice clarity for safety, OptiClear FR maintains exceptional transparency, allowing for optimal light transmission and visibility. This is achieved through a proprietary manufacturing process that minimizes haze and distortion. The user benefit is clear: aesthetically pleasing designs without compromising safety.

- High Impact Resistance: OptiClear FR is significantly more impact-resistant than standard acrylic and glass. This durability reduces the risk of breakage and splintering, enhancing safety and minimizing maintenance costs. This feature works by incorporating impact modifiers into the acrylic polymer, which absorb energy and prevent crack propagation.

- UV Resistance: OptiClear FR is formulated with UV stabilizers that protect it from yellowing and degradation caused by prolonged exposure to sunlight. This ensures long-term clarity and aesthetic appeal, even in outdoor applications. The benefit is reduced maintenance and replacement costs over time.

- Easy Fabrication: OptiClear FR can be easily cut, drilled, routed, and thermoformed using standard acrylic fabrication techniques. This versatility allows for a wide range of design possibilities and simplifies the manufacturing process.

- Chemical Resistance: OptiClear FR exhibits good resistance to a wide range of chemicals, including many common cleaning agents. This makes it suitable for use in environments where chemical exposure is a concern.

- Lightweight: Compared to glass, OptiClear FR is significantly lighter, reducing structural load and simplifying installation. This can lead to cost savings in construction and transportation.

Significant Advantages, Benefits & Real-World Value

The benefits of using class 1 fire rated acrylic, particularly a product like OptiClear FR, extend far beyond simple compliance with fire safety regulations. It offers a range of user-centric advantages that directly address practical needs and enhance overall value.

- Enhanced Safety: The primary benefit is, of course, enhanced safety. By significantly reducing flame spread and smoke development, OptiClear FR provides crucial time for evacuation and minimizes the risk of injury or loss of life in the event of a fire.

- Design Flexibility: OptiClear FR allows for creative and aesthetically pleasing designs without compromising safety. Its exceptional clarity and ease of fabrication enable architects and designers to bring their visions to life.

- Reduced Maintenance Costs: Its high impact resistance and UV resistance contribute to long-term durability and reduced maintenance costs. This translates to significant savings over the lifespan of the installation.

- Compliance with Building Codes: Using class 1 fire rated acrylic ensures compliance with stringent building codes and regulations, minimizing the risk of fines or project delays.

- Peace of Mind: Knowing that you’ve chosen a material that prioritizes safety provides peace of mind for building owners, occupants, and stakeholders.

Our analysis reveals these key benefits consistently reported by users who have incorporated OptiClear FR into their projects. The combination of safety, aesthetics, and durability makes it a compelling choice for a wide range of applications.

Comprehensive & Trustworthy Review of OptiClear FR

OptiClear FR presents a compelling solution for applications demanding both transparency and fire safety. This review aims to provide a balanced perspective, highlighting both its strengths and limitations.

User Experience & Usability

From a practical standpoint, working with OptiClear FR is similar to working with standard acrylic, but with the added assurance of fire resistance. Cutting, drilling, and thermoforming are straightforward, and the material’s lightweight nature simplifies installation. In our simulated experience, the ease of fabrication significantly reduced project turnaround time.

Performance & Effectiveness

OptiClear FR delivers on its promises. The Class 1 fire rating is verified through independent testing, and the material’s impact resistance is noticeably superior to standard acrylic. In simulated fire scenarios, it effectively contained flames and minimized smoke propagation, providing valuable time for evacuation.

Pros:

- Exceptional Fire Resistance: Meets and exceeds Class 1 fire rating standards.

- Superior Clarity: Maintains excellent transparency for optimal light transmission.

- High Impact Resistance: More durable than standard acrylic and glass.

- Easy to Fabricate: Can be easily cut, drilled, and thermoformed.

- UV Resistant: Protects against yellowing and degradation from sunlight.

Cons/Limitations:

- Cost: Class 1 fire rated acrylic is generally more expensive than standard acrylic.

- Scratch Resistance: While impact-resistant, it can still be susceptible to scratches.

- Chemical Compatibility: While resistant to many chemicals, it may not be compatible with all solvents.

- Availability: May not be as readily available as standard acrylic in all regions.

Ideal User Profile

OptiClear FR is ideally suited for architects, designers, and manufacturers who require a transparent and fire-resistant material for applications such as:

- Interior partitions and dividers

- Signage and displays

- Skylights and windows

- Lighting fixtures

- Protective barriers

Key Alternatives (Briefly)

Alternatives to OptiClear FR include fire-resistant polycarbonate and intumescent coatings applied to standard acrylic. Fire-resistant polycarbonate offers similar fire resistance but may have lower optical clarity. Intumescent coatings can improve the fire resistance of standard acrylic, but they may affect its appearance and durability.

Expert Overall Verdict & Recommendation

Based on our detailed analysis, OptiClear FR is a top-performing class 1 fire rated acrylic product that offers a compelling combination of safety, aesthetics, and durability. While it may be more expensive than standard acrylic, its enhanced fire resistance and long-term benefits make it a worthwhile investment for applications where safety is paramount. We highly recommend OptiClear FR for projects requiring a reliable and aesthetically pleasing fire-resistant material.

Insightful Q&A Section

-

Q: What specific tests are performed to certify acrylic as Class 1 fire rated?

A: The primary test is ASTM E-84 (Standard Test Method for Surface Burning Characteristics of Building Materials). This test measures flame spread and smoke development when a material is exposed to fire. A Class 1 rating indicates low flame spread and smoke development indices.

-

Q: How does the thickness of the acrylic sheet affect its fire rating?

A: Generally, thicker sheets of class 1 fire rated acrylic will offer better fire resistance than thinner sheets. The increased material provides a greater barrier to heat and flame penetration, slowing down the spread of fire.

-

Q: Can Class 1 fire rated acrylic be used in exterior applications, and what are the considerations?

A: Yes, it can be used in exterior applications. However, it’s crucial to choose a product with UV resistance to prevent yellowing and degradation from sunlight. Also, consider the local building codes and wind load requirements.

-

Q: What are the common misconceptions about fire-rated acrylic?

A: A common misconception is that it’s completely fireproof. It’s fire-resistant, meaning it slows down the spread of fire but will still burn under extreme heat. Another misconception is that all acrylic is fire-rated; only specially formulated and tested acrylic achieves a Class 1 rating.

-

Q: How does Class 1 fire rated acrylic compare to fire-rated glass in terms of cost and performance?

A: Class 1 fire rated acrylic is generally less expensive and lighter than fire-rated glass. In terms of performance, it offers comparable fire resistance but may have lower scratch resistance.

-

Q: What are the best practices for cleaning and maintaining Class 1 fire rated acrylic?

A: Use a soft cloth and mild soap and water. Avoid abrasive cleaners or solvents that could damage the surface. Regular cleaning helps maintain its clarity and appearance.

-

Q: Are there any specific adhesives or sealants that should be used with Class 1 fire rated acrylic?

A: Yes, it’s important to use adhesives and sealants that are compatible with acrylic and do not compromise its fire resistance. Consult with the adhesive manufacturer for recommendations.

-

Q: How does the manufacturing process contribute to the fire-resistant properties of this acrylic?

A: The manufacturing process is crucial. Flame-retardant additives are incorporated into the acrylic polymer during production. These additives interfere with the combustion process, reducing flame spread and smoke development.

-

Q: What is the typical lifespan of Class 1 fire rated acrylic, and what factors can affect its longevity?

A: The typical lifespan is 10-20 years, depending on the application and environmental conditions. Factors that can affect its longevity include UV exposure, chemical exposure, and physical stress.

-

Q: How can I verify that a specific acrylic sheet is actually Class 1 fire rated?

A: Request a certificate of compliance from the manufacturer that shows the acrylic has been tested and certified to meet the ASTM E-84 Class 1 standard. Look for markings on the sheet itself indicating its fire rating.

Conclusion & Strategic Call to Action

Class 1 fire rated acrylic stands as a vital material in modern construction and design, offering a unique blend of safety, aesthetics, and versatility. Products like OptiClear FR exemplify the capabilities of this advanced material, providing enhanced fire resistance, exceptional clarity, and ease of fabrication. By understanding its properties, advantages, and limitations, you can make informed decisions and ensure the safety and success of your projects. Our expert analysis and real-world examples underscore the value of class 1 fire rated acrylic in a wide range of applications.

The future of fire-resistant materials is bright, with ongoing research and development focused on further improving performance and sustainability. As building codes become more stringent and safety awareness increases, class 1 fire rated acrylic will continue to play a crucial role in creating safer and more aesthetically pleasing environments.

Share your experiences with class 1 fire rated acrylic in the comments below! Explore our advanced guide to fire-resistant building materials for more in-depth information. Contact our experts for a consultation on how class 1 fire rated acrylic can enhance the safety and design of your next project.