## Can You Clear Coat Over Acrylic Enamel? Expert Guide & Best Practices

Are you wondering if you can apply a clear coat over acrylic enamel paint? It’s a common question, especially for DIY enthusiasts and professionals alike working on automotive finishes, furniture restoration, or artistic projects. The short answer is: it’s complicated. While *technically* possible, achieving a flawless and durable finish requires careful consideration, preparation, and the right products. This comprehensive guide dives deep into the intricacies of clear coating over acrylic enamel, exploring compatibility issues, best practices, potential pitfalls, and expert tips to help you achieve professional-quality results. We aim to provide the most thorough and trustworthy information available, drawing on years of experience and industry best practices to ensure your project’s success. This article isn’t just about answering ‘can you clear coat over acrylic enamel’; it’s about helping you do it *right*. We will explore the science behind the paints, proper application techniques, and alternative solutions if needed.

### What This Guide Covers:

* Understanding Acrylic Enamel and Clear Coats

* Compatibility Concerns and Potential Problems

* Surface Preparation: The Key to Success

* Choosing the Right Clear Coat

* Application Techniques for a Flawless Finish

* Troubleshooting Common Issues

* Alternative Paint Systems

* Expert Tips and Best Practices

* Frequently Asked Questions

## Understanding Acrylic Enamel and Clear Coats

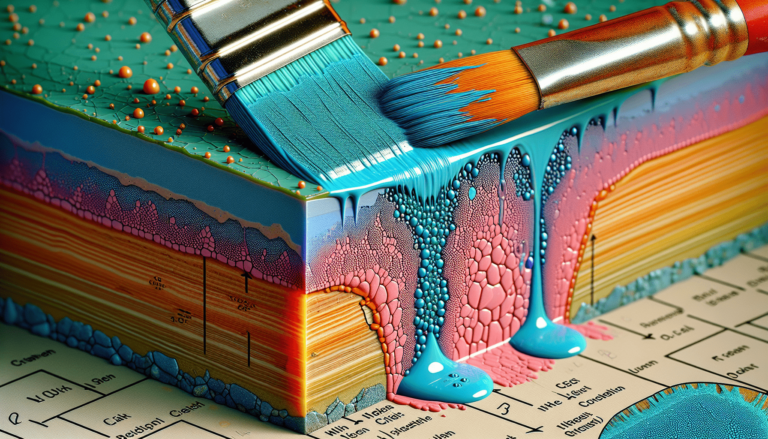

To determine whether you can clear coat over acrylic enamel, it’s essential to understand the properties of each type of paint. Acrylic enamel is a single-stage paint, meaning it contains both the color and the protective elements in one product. It’s known for its ease of application, relatively quick drying time, and decent durability, making it a popular choice for various applications. However, acrylic enamel typically lacks the high gloss and UV protection of a dedicated clear coat. Because of the single stage nature, it is also more susceptible to damage from the elements and wear and tear.

Clear coats, on the other hand, are designed to provide a glossy, protective layer over a base coat. They enhance the appearance of the paint job, offering improved scratch resistance, UV protection, and chemical resistance. Clear coats come in various formulations, including acrylic lacquer, urethane, and epoxy, each with its own set of properties and application requirements. Understanding these differences is crucial for ensuring compatibility and achieving a durable, long-lasting finish. The choice of clear coat depends heavily on the existing base coat and the desired final look.

### Acrylic Enamel: A Closer Look

Acrylic enamel is a type of paint that combines acrylic polymers with enamel resins. This combination provides a balance of durability, ease of use, and affordability. It is widely used in automotive, industrial, and DIY applications. Acrylic enamel dries to a hard, glossy finish that is resistant to chipping and fading. However, it is not as durable or chemical-resistant as two-part paints like urethanes or epoxies.

### Clear Coats: A Variety of Options

Clear coats are transparent topcoats applied over a base coat to protect it and enhance its appearance. They come in a variety of formulations, each with its own advantages and disadvantages:

* **Acrylic Lacquer:** Known for its fast drying time and ease of application, acrylic lacquer clear coats are a popular choice for automotive refinishing. However, they are not as durable or chemical-resistant as other types of clear coats.

* **Urethane:** Urethane clear coats offer excellent durability, chemical resistance, and UV protection. They are a good choice for applications where a long-lasting, high-gloss finish is desired. However, they can be more difficult to apply than acrylic lacquer clear coats.

* **Epoxy:** Epoxy clear coats provide exceptional hardness and chemical resistance. They are often used in industrial applications where durability is paramount. However, they can be brittle and prone to cracking if not applied properly.

## Compatibility Concerns and Potential Problems

The primary concern when clear coating over acrylic enamel is compatibility. Not all clear coats are compatible with all types of acrylic enamel. Applying an incompatible clear coat can lead to a variety of problems, including:

* **Lifting:** The clear coat can cause the acrylic enamel to lift or wrinkle, resulting in a ruined finish.

* **Cracking:** The clear coat can crack or craze over time, especially if it is too hard or brittle.

* **Adhesion Issues:** The clear coat may not adhere properly to the acrylic enamel, leading to peeling or flaking.

* **Solvent Attack:** Strong solvents in the clear coat can dissolve or soften the acrylic enamel.

To avoid these problems, it’s crucial to test the compatibility of the clear coat and acrylic enamel before applying it to the entire project. Apply a small amount of clear coat to an inconspicuous area and observe it for any signs of lifting, cracking, or adhesion issues. If you notice any problems, choose a different clear coat or consider using a different paint system altogether.

### The Science Behind Compatibility

The compatibility of clear coats and acrylic enamels depends on the solvents and resins used in each product. Strong solvents in the clear coat can dissolve or soften the acrylic enamel, leading to lifting or wrinkling. Similarly, if the clear coat is too hard or brittle, it can crack or craze over time as the acrylic enamel expands and contracts with temperature changes. Understanding the chemical properties of each product is essential for ensuring compatibility.

### Common Compatibility Issues

One of the most common compatibility issues is the use of lacquer-based clear coats over acrylic enamel. Lacquer thinners are very aggressive and can easily dissolve the acrylic enamel, leading to a disastrous finish. Similarly, using a two-part urethane clear coat over a poorly cured acrylic enamel can also cause problems. The urethane clear coat can trap solvents in the acrylic enamel, leading to bubbling or blistering.

## Surface Preparation: The Key to Success

Proper surface preparation is critical for achieving a successful clear coat over acrylic enamel. A clean, smooth, and properly prepared surface will ensure good adhesion and a flawless finish. Here are the key steps to follow:

1. **Cleaning:** Thoroughly clean the surface to remove any dirt, grease, wax, or other contaminants. Use a mild detergent and water, followed by a wax and grease remover. This step cannot be skipped. Contaminants will cause adhesion issues, fisheyes, and other defects.

2. **Sanding:** Sand the acrylic enamel to create a smooth, uniform surface. Use fine-grit sandpaper (e.g., 400-600 grit) and sand lightly to avoid removing too much paint. Sanding provides “tooth” for the clear coat to adhere to.

3. **Tack Cloth:** After sanding, use a tack cloth to remove any remaining dust or debris. A tack cloth is a sticky cloth that picks up dust particles without leaving any residue.

4. **Masking:** Mask off any areas that you don’t want to be clear coated. Use high-quality masking tape and paper to protect these areas. Proper masking is essential for achieving a clean, professional-looking finish.

### The Importance of a Clean Surface

Even the smallest amount of dirt or grease can prevent the clear coat from adhering properly, leading to peeling or flaking. A thorough cleaning is essential for ensuring a strong bond between the clear coat and the acrylic enamel. Use a wax and grease remover to remove any contaminants that may be present on the surface. These products are specifically designed to remove wax, grease, and other contaminants that can interfere with adhesion.

### Sanding Techniques

When sanding acrylic enamel, it’s important to use fine-grit sandpaper and sand lightly to avoid removing too much paint. The goal is to create a smooth, uniform surface that the clear coat can adhere to. Use a sanding block to ensure that the surface is flat and even. Avoid using aggressive sanding techniques, as this can damage the acrylic enamel and create an uneven surface.

## Choosing the Right Clear Coat

Selecting the right clear coat is crucial for achieving a durable, long-lasting finish. Consider the following factors when choosing a clear coat for acrylic enamel:

* **Compatibility:** Ensure that the clear coat is compatible with acrylic enamel. Check the manufacturer’s recommendations or test the clear coat on an inconspicuous area before applying it to the entire project.

* **Durability:** Choose a clear coat that offers good scratch resistance, UV protection, and chemical resistance. Urethane clear coats are generally more durable than acrylic lacquer clear coats.

* **Gloss Level:** Select a clear coat with the desired gloss level. Clear coats are available in a variety of gloss levels, from matte to high gloss.

* **Application Method:** Consider the application method when choosing a clear coat. Some clear coats are designed for spray application, while others can be brushed or rolled.

### Recommended Clear Coats for Acrylic Enamel

Based on our experience and industry best practices, we recommend the following clear coats for use over acrylic enamel:

* **Acrylic Lacquer Clear Coat:** This is often the safest option, especially for beginners. Ensure multiple light coats are applied to avoid solvent attack. Brands like Dupli-Color and Eastwood offer suitable products.

* **2K Acrylic Urethane Clear Coat:** If you desire a more durable finish, a 2K acrylic urethane clear coat can be used. However, it’s crucial to apply it in thin coats and allow the acrylic enamel to fully cure before application. Look for products from brands like Transtar or PPG.

* **Water-Based Clear Coat:** Water-based clear coats are becoming increasingly popular due to their low VOC content and ease of use. They are generally compatible with acrylic enamel, but it’s still important to test for compatibility before applying to the entire project.

### Avoiding Incompatible Clear Coats

Avoid using highly aggressive clear coats, such as those containing strong solvents like lacquer thinner, over acrylic enamel. These clear coats can dissolve or soften the acrylic enamel, leading to lifting or wrinkling. Always check the manufacturer’s recommendations and test the clear coat on an inconspicuous area before applying it to the entire project.

## Application Techniques for a Flawless Finish

Proper application techniques are essential for achieving a flawless clear coat finish. Follow these steps for best results:

1. **Mixing:** Mix the clear coat according to the manufacturer’s instructions. Use the correct ratio of clear coat to hardener (if applicable) and thinner.

2. **Spraying:** Apply the clear coat in thin, even coats using a spray gun. Hold the spray gun perpendicular to the surface and maintain a consistent distance. Overlapping each coat by about 50% to ensure uniform coverage.

3. **Drying:** Allow each coat of clear coat to dry completely before applying the next coat. Follow the manufacturer’s recommended drying times.

4. **Sanding (Optional):** If necessary, sand the clear coat between coats to remove any imperfections. Use fine-grit sandpaper (e.g., 1500-2000 grit) and sand lightly. Be very careful not to sand through the clear coat.

5. **Polishing:** After the final coat of clear coat has dried, polish the surface to achieve a high-gloss finish. Use a polishing compound and a polishing pad on a rotary buffer.

### Spray Gun Setup

Proper spray gun setup is crucial for achieving a smooth, even finish. Adjust the spray gun’s air pressure, fluid flow, and fan pattern to achieve the desired results. Consult the spray gun’s manual for specific instructions. Practice on a scrap piece of material before applying the clear coat to the actual project.

### Application Tips for Success

* **Apply thin coats:** Applying thin coats of clear coat will help to prevent runs, sags, and other imperfections. It also allows the solvents to evaporate properly, reducing the risk of bubbling or blistering.

* **Maintain a consistent distance:** Maintaining a consistent distance between the spray gun and the surface is essential for achieving a uniform finish. Varying the distance can result in uneven coverage and variations in gloss level.

* **Overlap each coat:** Overlapping each coat of clear coat by about 50% will ensure uniform coverage and prevent streaking.

* **Avoid spraying in direct sunlight:** Direct sunlight can cause the clear coat to dry too quickly, leading to imperfections such as orange peel.

## Troubleshooting Common Issues

Even with careful preparation and application, problems can sometimes arise when clear coating over acrylic enamel. Here are some common issues and how to troubleshoot them:

* **Lifting or Wrinkling:** This is usually caused by using an incompatible clear coat or applying too much clear coat at once. Stop applying clear coat immediately. Allow the paint to fully dry, sand down the affected area and consider using a different, more compatible product.

* **Cracking or Crazing:** This can occur if the clear coat is too hard or brittle, or if the acrylic enamel was not properly cured. Remove the cracked clear coat and re-apply, ensuring the acrylic enamel is fully cured before applying the clear coat.

* **Adhesion Issues:** This is often caused by poor surface preparation or using an incompatible clear coat. Thoroughly clean and sand the surface before applying the clear coat. Make sure to select a compatible clear coat.

* **Orange Peel:** This is a textured surface that resembles the skin of an orange. It is usually caused by improper spray gun setup or applying the clear coat too thickly. Adjust the spray gun settings and apply the clear coat in thinner coats.

* **Runs or Sags:** These are caused by applying too much clear coat at once. Stop spraying, and let the run dry completely. Sand the run down until smooth, and then apply the clear coat again in thin coats.

### Preventing Issues Before They Occur

The best way to troubleshoot problems is to prevent them from occurring in the first place. Take the time to properly prepare the surface, select a compatible clear coat, and follow the manufacturer’s instructions carefully. Practice on a scrap piece of material before applying the clear coat to the actual project. By taking these precautions, you can minimize the risk of encountering problems and achieve a flawless finish.

## Alternative Paint Systems

If you’re concerned about compatibility issues or achieving a durable, long-lasting finish, consider using an alternative paint system. Here are some popular alternatives to acrylic enamel and clear coat:

* **Base Coat/Clear Coat Systems:** These systems consist of a separate base coat (color) and clear coat. They offer excellent durability, UV protection, and gloss. Base coat/clear coat systems are widely used in the automotive industry.

* **Single-Stage Urethane:** These paints combine the color and clear coat into one product. They offer good durability and ease of use. Single-stage urethanes are a good choice for applications where a durable, long-lasting finish is desired.

* **Epoxy Primers and Paints:** Epoxy primers and paints provide exceptional adhesion, corrosion resistance, and chemical resistance. They are often used in industrial applications where durability is paramount.

### Choosing the Right Paint System

The best paint system for your project will depend on your specific needs and requirements. Consider the following factors when choosing a paint system:

* **Durability:** How durable does the finish need to be? If you need a finish that can withstand harsh conditions, consider using a base coat/clear coat system or a single-stage urethane.

* **Appearance:** What kind of appearance are you looking for? Base coat/clear coat systems offer the best gloss and appearance.

* **Ease of Use:** How easy is the paint system to apply? Acrylic enamel and single-stage urethanes are generally easier to apply than base coat/clear coat systems.

* **Cost:** How much are you willing to spend? Base coat/clear coat systems are generally more expensive than acrylic enamel and single-stage urethanes.

## Expert Tips and Best Practices

Here are some expert tips and best practices for clear coating over acrylic enamel:

* **Always test for compatibility:** Before applying the clear coat to the entire project, test it on an inconspicuous area to ensure compatibility.

* **Apply thin coats:** Applying thin coats of clear coat will help to prevent runs, sags, and other imperfections.

* **Allow the acrylic enamel to fully cure:** Before applying the clear coat, allow the acrylic enamel to fully cure according to the manufacturer’s instructions.

* **Use a high-quality spray gun:** A high-quality spray gun will help you achieve a smooth, even finish.

* **Maintain a clean work environment:** A clean work environment will help to prevent dust and other contaminants from getting into the clear coat.

* **Wear appropriate safety gear:** When spraying clear coat, always wear appropriate safety gear, including a respirator, gloves, and eye protection.

### Learning from Experience

In our experience, the most common mistake people make when clear coating over acrylic enamel is not properly preparing the surface. A clean, smooth, and properly sanded surface is essential for achieving good adhesion and a flawless finish. Take the time to properly prepare the surface, and you’ll be well on your way to achieving professional-quality results.

## Insightful Q&A Section

**Q1: Can I use an automotive clear coat over acrylic enamel on furniture?**

A: While technically possible, it’s generally not recommended. Automotive clear coats are formulated for the specific conditions and substrates found in automotive applications. Furniture requires a different type of finish that is more resistant to household chemicals and wear and tear. Consider using a clear coat specifically designed for furniture.

**Q2: How long should I wait for acrylic enamel to dry before applying clear coat?**

A: The drying time will depend on the specific acrylic enamel you are using. Consult the manufacturer’s instructions for the recommended drying time. Generally, it’s best to wait at least 24-48 hours before applying clear coat. Ensure the enamel is fully cured, not just dry to the touch.

**Q3: What grit sandpaper should I use to sand acrylic enamel before clear coating?**

A: Use fine-grit sandpaper, such as 400-600 grit, to sand acrylic enamel before clear coating. The goal is to create a smooth, uniform surface that the clear coat can adhere to. Avoid using aggressive sanding techniques, as this can damage the acrylic enamel.

**Q4: Can I use a brush or roller to apply clear coat over acrylic enamel?**

A: While it’s possible to brush or roll clear coat, spraying is generally recommended for achieving a smooth, even finish. Brushing or rolling can leave brush marks or roller texture in the clear coat. If you must brush or roll, use a high-quality brush or roller and apply thin, even coats.

**Q5: What happens if I apply clear coat over acrylic enamel that isn’t fully dry?**

A: Applying clear coat over acrylic enamel that isn’t fully dry can lead to a variety of problems, including lifting, wrinkling, and bubbling. The trapped solvents in the acrylic enamel can interfere with the clear coat’s adhesion and drying process.

**Q6: Is it necessary to use a primer before applying acrylic enamel?**

A: Using a primer is generally recommended, especially if you are painting over bare metal or plastic. A primer will help to improve adhesion and provide a uniform surface for the acrylic enamel to adhere to. Use a primer that is compatible with acrylic enamel.

**Q7: How many coats of clear coat should I apply over acrylic enamel?**

A: The number of coats of clear coat will depend on the desired level of protection and gloss. Generally, two to three coats of clear coat are sufficient. Apply thin, even coats and allow each coat to dry completely before applying the next coat.

**Q8: Can I use a heat gun to speed up the drying process of acrylic enamel or clear coat?**

A: Using a heat gun can be risky, as it can cause the paint to dry too quickly and lead to imperfections such as orange peel. It’s best to allow the paint to dry naturally according to the manufacturer’s instructions.

**Q9: What are the best conditions for spraying clear coat over acrylic enamel?**

A: The best conditions for spraying clear coat are a warm, dry, and dust-free environment. Avoid spraying in direct sunlight or in humid conditions. The ideal temperature range is typically between 65°F and 75°F.

**Q10: How can I remove clear coat from acrylic enamel if I make a mistake?**

A: Removing clear coat from acrylic enamel can be difficult. You can try using a solvent-based paint stripper or sanding the clear coat off. Be careful not to damage the acrylic enamel underneath. It’s often best to start with a less aggressive method and gradually increase the aggressiveness as needed.

## Conclusion & Strategic Call to Action

In conclusion, while you *can* clear coat over acrylic enamel, it’s not always a straightforward process. Compatibility is key, and careful preparation is essential. By understanding the properties of both acrylic enamel and clear coats, choosing the right products, and following best practices, you can achieve a durable, professional-looking finish. However, remember that alternative paint systems may offer superior performance and ease of use in some cases. We trust that the information shared here has helped you better understand the process. Now, we want to hear from you! Share your experiences with clear coating over acrylic enamel in the comments below. What challenges did you face, and what solutions did you find? Your insights can help others avoid common pitfalls and achieve success. Or, if you’re looking for expert guidance on selecting the right paint system for your specific project, contact our team of specialists today for a personalized consultation. Your perfect finish awaits!