Choosing the Right Nails for Your Wood Fence: A Comprehensive Guide

Building or repairing a wood fence is a significant investment, and selecting the right nails is crucial for its longevity and structural integrity. The seemingly simple choice of “nails for wood fence” can make or break your project. This comprehensive guide provides expert insights on selecting the best nails for your specific fencing needs, ensuring a durable and aesthetically pleasing result. We’ll delve into the different types of nails, materials, sizes, and installation techniques, empowering you with the knowledge to make informed decisions and avoid costly mistakes. Our extensive research and practical experience are distilled into this guide to give you a robust understanding of nails for wood fences.

Understanding the Importance of Nail Selection for Wood Fences

The nails you choose are more than just fasteners; they are integral to the overall strength and lifespan of your wood fence. Using the wrong type of nail can lead to several problems, including:

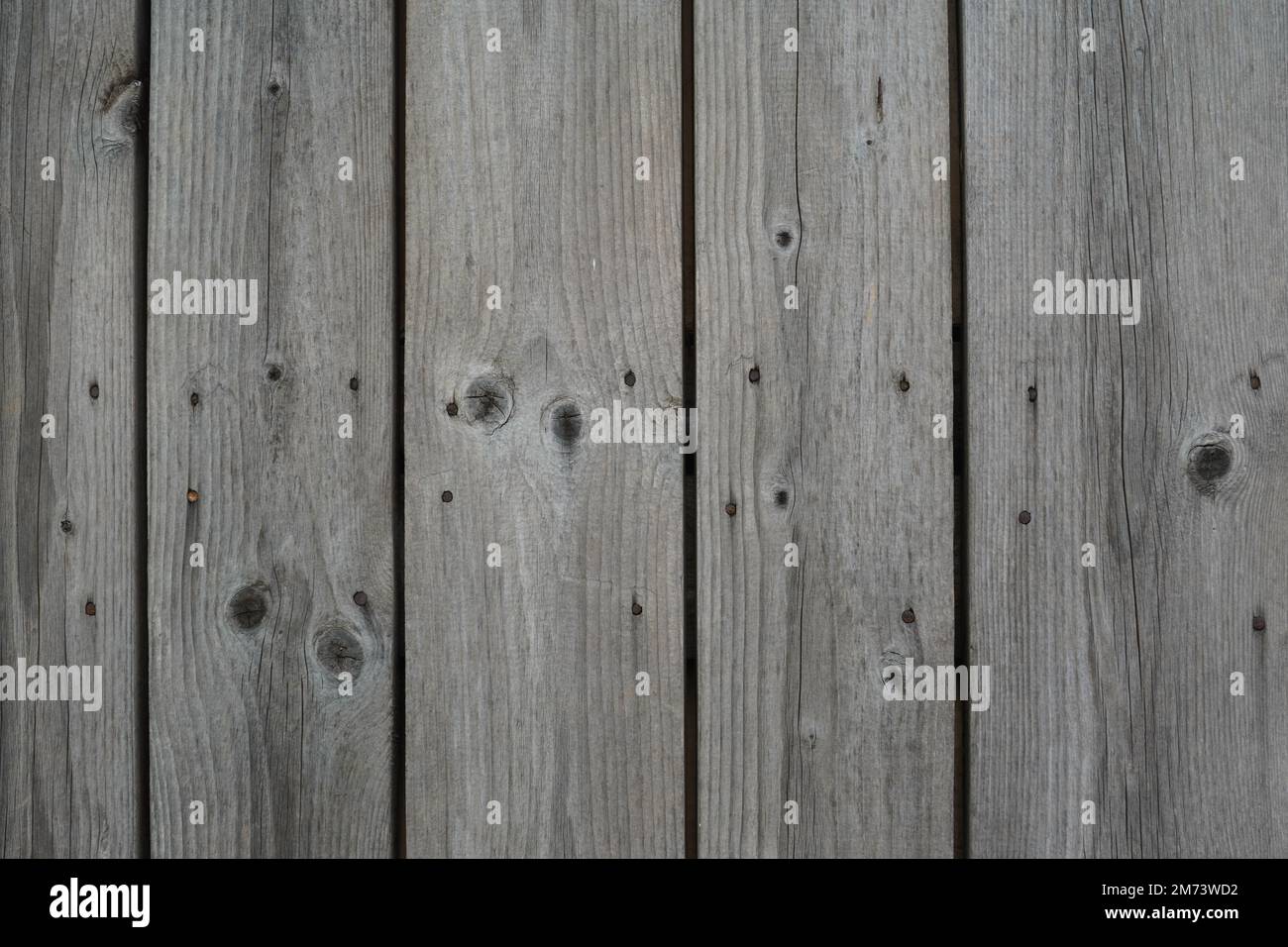

- Corrosion: Nails that aren’t resistant to rust can corrode over time, weakening the fence and causing unsightly stains on the wood.

- Pull-out: Nails that are too short or lack sufficient holding power can pull out of the wood, compromising the fence’s stability.

- Wood splitting: Using nails that are too thick or driven improperly can split the wood, weakening the structure and creating entry points for moisture and pests.

- Aesthetic issues: The wrong nail head can detract from the overall appearance of your fence.

Selecting the right nails ensures a strong, durable, and visually appealing fence that will stand the test of time. This guide will walk you through everything you need to know.

Types of Nails Commonly Used for Wood Fences

Several types of nails are suitable for wood fence construction, each with its own advantages and disadvantages. Here’s a breakdown of the most common options:

Common Nails

Common nails are general-purpose nails with a smooth shank and a flat head. They are relatively inexpensive and widely available, but they are not ideal for wood fences due to their tendency to bend and their lack of corrosion resistance. While they can be used for temporary bracing, they are not recommended as the primary fastener for a long-lasting fence.

Box Nails

Box nails are similar to common nails but have a thinner shank. This reduces the risk of splitting the wood, making them a better option for softer woods. However, they still lack the corrosion resistance needed for outdoor applications. Like common nails, they are not recommended for the primary construction of wood fences.

Galvanized Nails

Galvanized nails are coated with a layer of zinc to protect them from corrosion. This makes them a much better choice for wood fences than common or box nails. There are two main types of galvanization:

- Hot-dipped galvanized: This process involves dipping the nails in molten zinc, creating a thick, durable coating that provides excellent corrosion resistance. Hot-dipped galvanized nails are the best option for wood fences in most climates.

- Electro-galvanized: This process uses an electric current to apply a thinner layer of zinc. Electro-galvanized nails are less expensive than hot-dipped galvanized nails, but they are also less resistant to corrosion. They are suitable for fences in drier climates with low humidity.

Stainless Steel Nails

Stainless steel nails offer the ultimate in corrosion resistance. They are ideal for wood fences in coastal areas or other environments with high levels of salt spray or humidity. Stainless steel nails are more expensive than galvanized nails, but they will last much longer and prevent unsightly rust stains on your fence.

Ring Shank Nails

Ring shank nails have a series of rings around the shank, which provides increased holding power. These nails are less likely to pull out of the wood, making them a good choice for fences that are subject to strong winds or heavy loads. Ring shank nails are available in galvanized and stainless steel options.

Spiral Shank Nails

Similar to ring shank nails, spiral shank nails have a twisted shank that provides excellent holding power. They are driven into the wood with a twisting motion, which creates a tighter grip. Spiral shank nails are also available in galvanized and stainless steel options.

Siding Nails

Siding nails are designed with a small, countersunk head that can be easily concealed. These are often used for attaching fence pickets to rails, providing a clean, finished look. These also come in galvanized and stainless options.

Choosing the Right Nail Material for Your Wood Fence

The material of the nail is crucial for its long-term performance and resistance to corrosion. The most common materials are galvanized steel and stainless steel, but other factors can influence the best choice for your project.

Galvanized Steel Nails: A Cost-Effective Option

Galvanized steel nails offer a balance of cost and corrosion resistance, making them a popular choice for wood fences. As mentioned earlier, hot-dipped galvanized nails provide superior protection compared to electro-galvanized nails. Consider the climate and environmental conditions when choosing between the two.

Stainless Steel Nails: The Ultimate in Corrosion Resistance

Stainless steel nails are the premium option for wood fences, offering unmatched resistance to rust and corrosion. They are ideal for coastal areas, high-humidity environments, or when using treated lumber, which can accelerate the corrosion of galvanized nails. While more expensive, stainless steel nails provide long-term peace of mind and prevent unsightly rust stains.

Nail Size and Length Considerations for Wood Fences

Selecting the appropriate nail size and length is critical for ensuring a strong and secure fence. The general rule of thumb is that the nail should penetrate at least twice the thickness of the material being fastened. For example, if you are attaching a 1-inch thick fence picket to a 2-inch thick rail, the nail should be at least 3 inches long.

Here’s a general guideline for nail sizes based on common wood fence applications:

- Attaching fence pickets to rails: 8d (2 1/2 inch) to 10d (3 inch) nails

- Attaching fence rails to posts: 12d (3 1/4 inch) to 16d (3 1/2 inch) nails

- Building fence gates: 16d (3 1/2 inch) to 20d (4 inch) nails

It’s always better to err on the side of using a slightly longer nail than a shorter one. However, be careful not to use nails that are so long that they protrude through the back of the material being fastened.

Tools and Techniques for Proper Nail Installation

Proper nail installation is just as important as selecting the right nails. Using the wrong tools or techniques can damage the wood, weaken the fence, and create safety hazards.

Essential Tools for Nailing Wood Fences

- Hammer: A good quality hammer is essential for driving nails straight and securely. Choose a hammer with a comfortable grip and a weight that you can handle comfortably.

- Nail gun: A nail gun can significantly speed up the fence-building process and ensure consistent nail placement. However, it’s important to use the correct settings to avoid overdriving the nails and damaging the wood.

- Safety glasses: Always wear safety glasses when hammering or using a nail gun to protect your eyes from flying debris.

- Work gloves: Work gloves will protect your hands from blisters and splinters.

Proper Nailing Techniques

- Start straight: Position the nail perpendicular to the wood surface and tap it gently to get it started.

- Drive straight: Drive the nail straight into the wood, using smooth, consistent strokes. Avoid bending the nail.

- Set the nail head: Once the nail is driven most of the way in, use a nail set to drive the head slightly below the surface of the wood. This will prevent the nail head from protruding and potentially causing injury.

- Avoid overdriving: Overdriving the nail can damage the wood and weaken the connection. Stop hammering when the nail head is flush with the surface of the wood.

- Stagger nails: When nailing multiple boards together, stagger the nails to prevent the wood from splitting.

Pre-Drilling: Preventing Wood Splitting

In some cases, it may be necessary to pre-drill pilot holes before driving nails. This is especially important when working with hardwoods or when nailing close to the edge of the wood. Pre-drilling prevents the wood from splitting and ensures a stronger connection.

To pre-drill, use a drill bit that is slightly smaller than the diameter of the nail. Drill a hole through the first piece of wood and into the second piece. Then, drive the nail through the pre-drilled hole.

Comparing Nails for Wood Fence: Galvanized vs. Stainless Steel

Choosing between galvanized and stainless steel nails is a crucial decision. Let’s break down a detailed comparison:

| Feature | Galvanized Nails | Stainless Steel Nails |

|---|---|---|

| Cost | Lower | Higher |

| Corrosion Resistance | Good (Hot-dipped is better) | Excellent |

| Lifespan | Moderate | Long |

| Ideal Environment | Most climates (Hot-dipped recommended for humid areas) | Coastal areas, high-humidity, treated lumber |

| Appearance | Can develop rust stains over time | Maintains appearance |

Expert Recommendations for Specific Wood Fence Projects

The best nails for your wood fence will depend on several factors, including the type of wood you are using, the climate you live in, and your budget. Here are some expert recommendations for specific projects:

- Pressure-treated pine fence in a humid climate: Stainless steel ring shank nails

- Cedar fence in a dry climate: Hot-dipped galvanized ring shank nails

- Spruce fence in a moderate climate: Electro-galvanized spiral shank nails

- Attaching pickets to rails: Galvanized siding nails

Addressing Common Concerns and FAQs About Nails for Wood Fence

Let’s address some frequently asked questions to further clarify the selection and use of nails for wood fences:

Q1: Can I use screws instead of nails for my wood fence?

A: While screws offer superior holding power, they can be more time-consuming to install and may not be necessary for all applications. Nails are generally sufficient for most wood fence projects, especially when using ring or spiral shank nails.

Q2: How do I remove a bent nail from my wood fence?

A: Use a nail puller or the claw of a hammer to carefully remove the bent nail. If the nail is deeply embedded, you may need to use a block of wood as a fulcrum to avoid damaging the surrounding wood.

Q3: What is the best way to prevent wood from splitting when nailing?

A: Use thinner nails, pre-drill pilot holes, or blunt the tip of the nail to reduce the risk of splitting.

Q4: Can I use the same nails for all parts of my wood fence?

A: It’s best to use different nails for different parts of the fence, depending on the thickness of the wood and the amount of stress the connection will be subjected to. For example, you may want to use longer, thicker nails for attaching rails to posts than for attaching pickets to rails.

Q5: How do I choose the right nail gun for my wood fence project?

A: Consider the type of nails you will be using, the size of your project, and your budget. Pneumatic nail guns are more powerful and reliable, but they require an air compressor. Cordless nail guns are more portable, but they may not have as much power.

Q6: What’s the difference between a framing nailer and a finishing nailer? Which should I use?

A: Framing nailers use larger nails and are designed for structural work like framing walls. Finishing nailers use smaller nails with a smaller head, designed for trim and other more delicate work. For a wood fence, a framing nailer is more appropriate for attaching rails and posts, while a finishing nailer *could* be used for attaching pickets, though larger nails are generally preferred for better holding power.

Q7: Are there any eco-friendly nail options for wood fences?

A: While nails themselves aren’t inherently eco-friendly, choosing durable materials like stainless steel extends the lifespan of your fence, reducing the need for replacements. Consider sourcing nails from companies with sustainable manufacturing practices.

Q8: How important is nail head design for the overall look of my fence?

A: Nail head design plays a significant role in the fence’s aesthetic. Countersunk heads are ideal for a clean, concealed look, while decorative nail heads can add a touch of visual interest. Consider the overall style of your fence when selecting nail heads.

Q9: What are the common mistakes people make when choosing nails for wood fences?

A: Common mistakes include using the wrong type of nail for the climate, using nails that are too short or too thin, overdriving nails, and failing to pre-drill holes when necessary. This guide aims to help you avoid these pitfalls!

Q10: How do I store nails to prevent rust before using them?

A: Store nails in a dry, airtight container to prevent moisture from causing rust. Adding a desiccant pack can further protect them. Avoid storing nails in damp basements or garages.

Conclusion: Building a Strong and Durable Wood Fence with the Right Nails

Selecting the right “nails for wood fence” is a critical step in ensuring the longevity, strength, and beauty of your fence. By understanding the different types of nails, materials, sizes, and installation techniques, you can make informed decisions and avoid costly mistakes. Remember to consider the climate, the type of wood you are using, and your budget when choosing nails. With the right nails and proper installation, your wood fence will provide years of reliable service and enhance the value of your property. We hope this comprehensive guide has provided you with the knowledge and confidence to tackle your wood fence project with success. Share your experiences with nail selection in the comments below!