Setting Metal Fence Posts in Concrete: A Definitive Guide

Are you looking to build a sturdy and long-lasting metal fence? The key to a successful fence installation lies in properly setting the metal fence posts in concrete. This comprehensive guide provides everything you need to know to ensure your fence stands the test of time. We’ll cover everything from planning and preparation to the actual setting process, including expert tips and techniques to avoid common pitfalls. This isn’t just another how-to guide; we’re sharing years of experience and best practices to help you achieve professional-quality results. Learn the ins and outs of **setting metal fence posts in concrete** and build a fence that not only looks great but also provides lasting security and value.

Understanding the Importance of Proper Post Setting

The strength and longevity of any fence depend heavily on the proper installation of its posts. When **setting metal fence posts in concrete**, you’re creating a stable foundation that resists wind, impact, and the natural forces of expansion and contraction. A poorly installed post can lead to leaning, wobbling, and ultimately, fence failure. This section delves into the crucial aspects of post setting, emphasizing why concrete is the preferred material for metal posts and highlighting the potential consequences of inadequate installation.

Why Concrete?

Concrete provides superior stability and support compared to other methods, such as simply burying the posts in the ground. Its compressive strength allows it to withstand significant loads, while its resistance to water and soil degradation ensures long-term durability. Furthermore, concrete anchors the post firmly in place, preventing movement and maintaining the fence’s structural integrity. From our experience, concrete provides the best long-term value for your fence.

Consequences of Improper Installation

Failing to properly set metal fence posts in concrete can result in a range of problems, including:

* **Leaning Posts:** This is the most common issue, caused by inadequate support or soil erosion around the post.

* **Wobbly Fence:** Loose posts compromise the entire fence structure, making it susceptible to damage.

* **Premature Deterioration:** Moisture and soil contact can corrode the metal post, shortening its lifespan.

* **Complete Fence Failure:** In severe cases, the fence may collapse entirely, requiring costly repairs or replacement.

Planning and Preparation: The Foundation for Success

Before you start digging, careful planning and preparation are essential. This section outlines the steps to take to ensure a smooth and successful fence installation. Consider this the blueprint for your project; skipping steps here can lead to major headaches later.

1. Define Your Fence Line and Obtain Necessary Permits

Accurately mark the boundaries of your fence using stakes and string. Check local regulations for any required permits or restrictions on fence height, materials, or placement. Failure to obtain necessary permits can result in fines or even forced removal of the fence. It’s always best to check with your local authorities before starting any construction project. This is a critical step in **setting metal fence posts in concrete**.

2. Choose the Right Metal Fence Posts

Select posts that are appropriate for your fence style and height. Consider the gauge (thickness) of the metal, as well as any protective coatings to prevent rust and corrosion. Common types include:

* **Steel Posts:** Strong and durable, but susceptible to rust if not properly coated.

* **Aluminum Posts:** Lightweight and rust-resistant, but may not be as strong as steel.

* **Galvanized Steel Posts:** Steel posts coated with zinc to prevent rust. A great option for longevity.

3. Calculate Post Spacing and Hole Depth

Determine the appropriate spacing between posts based on your fence design and the length of the fence panels. A general rule of thumb is to space posts 6-8 feet apart. The depth of the post holes should be at least one-third the height of the post above ground. For example, a 6-foot fence post should have at least 2 feet of its length buried in concrete. Proper depth is crucial for stability when **setting metal fence posts in concrete**.

4. Gather Your Tools and Materials

Make sure you have all the necessary tools and materials before you begin. This will save you time and frustration later on. Here’s a comprehensive list:

* Post Hole Digger or Auger

* Shovel

* Level

* Measuring Tape

* String Line

* Mixing Tub or Wheelbarrow

* Concrete Mix

* Water

* Gloves

* Safety Glasses

* Tamper (for compacting soil)

* Quick-setting concrete (optional, for faster setting)

Step-by-Step Guide: Setting Metal Fence Posts in Concrete

Now that you’ve planned and prepared, it’s time to get to work. This section provides a detailed, step-by-step guide to **setting metal fence posts in concrete**, ensuring a strong and stable foundation for your fence.

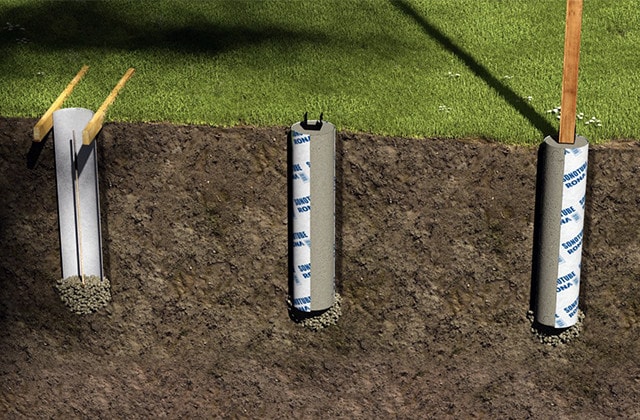

Step 1: Dig the Post Holes

Using a post hole digger or auger, dig the holes to the specified depth and diameter. The diameter of the hole should be at least 3 times the width of the post. This allows for adequate concrete coverage around the post. Ensure the sides of the hole are relatively straight and plumb. Remove any loose soil or debris from the bottom of the hole.

Step 2: Position the Post in the Hole

Carefully lower the post into the hole, ensuring it is centered and plumb. Use a level to check the post’s vertical alignment. If necessary, use shims or small stones to hold the post in place while you pour the concrete. Maintaining a plumb post is essential for a straight and professional-looking fence.

Step 3: Mix the Concrete

Follow the manufacturer’s instructions for mixing the concrete. Add water gradually until the mixture reaches a thick, oatmeal-like consistency. Avoid adding too much water, as this can weaken the concrete. Thoroughly mix the concrete to ensure it is free of lumps and evenly distributed.

Step 4: Pour the Concrete

Carefully pour the concrete into the hole around the post. Use a shovel or trowel to work the concrete around the post, ensuring it fills all the gaps and voids. Continue pouring until the concrete reaches the desired level, typically a few inches below the ground surface. This allows for a layer of topsoil or gravel to be added later.

Step 5: Check Plumb and Brace the Post

Recheck the post’s plumb using a level. Make any necessary adjustments to ensure the post is perfectly vertical. Use wooden braces to hold the post in place while the concrete sets. The braces should be securely attached to the post and anchored to the ground. Bracing is crucial to prevent movement during the curing process.

Step 6: Allow the Concrete to Cure

Allow the concrete to cure for at least 24-48 hours before removing the braces or attaching any fence panels. The curing process allows the concrete to harden and reach its full strength. Avoid disturbing the posts during this time. For optimal strength, allow the concrete to cure for 7 days. According to industry experts, proper curing is essential for long-term stability when **setting metal fence posts in concrete**.

Step 7: Backfill and Finish

Once the concrete has cured, remove the braces and backfill the hole with topsoil or gravel. Slope the soil away from the post to prevent water from pooling around the base. This helps to protect the post from corrosion and prolong its lifespan. You can also add a layer of mulch or decorative stones to enhance the appearance of the finished fence.

Choosing the Right Concrete Mix for Metal Fence Posts

The type of concrete mix you choose can significantly impact the strength and durability of your fence post foundations. Understanding the different types available and their specific properties is essential for making the right decision. A quality concrete mix is a worthwhile investment in the longevity of your fence.

Types of Concrete Mixes

* **Standard Concrete Mix:** This is a general-purpose mix suitable for most fence post applications. It typically consists of Portland cement, sand, and gravel.

* **Quick-Setting Concrete Mix:** This type of mix is designed to set much faster than standard concrete, allowing you to complete your fence installation more quickly. It’s ideal for situations where time is a constraint or when you need to minimize the risk of post movement during the curing process.

* **Fiber-Reinforced Concrete Mix:** This mix contains fibers that enhance its strength and resistance to cracking. It’s a good choice for areas with extreme weather conditions or where the fence is subject to heavy loads.

Factors to Consider When Choosing a Concrete Mix

* **Climate:** In colder climates, choose a concrete mix that is resistant to freeze-thaw cycles. In warmer climates, consider a mix that is less prone to cracking due to heat expansion.

* **Soil Conditions:** If the soil is acidic or contains high levels of sulfates, choose a concrete mix that is resistant to chemical attack.

* **Load Requirements:** If the fence will be subject to heavy loads, such as from strong winds or climbing plants, choose a concrete mix with higher compressive strength.

Troubleshooting Common Problems When Setting Metal Fence Posts in Concrete

Even with careful planning and execution, you may encounter problems when **setting metal fence posts in concrete**. This section addresses some common issues and provides solutions to help you overcome them.

Problem: The Post is Not Plumb

* **Solution:** Use shims or small stones to adjust the post’s position until it is perfectly vertical. Securely brace the post to prevent movement during the curing process. If the concrete has already started to set, you may need to break it up and re-pour it.

Problem: The Concrete is Cracking

* **Solution:** Ensure you are using the correct concrete mix for your climate and soil conditions. Avoid adding too much water to the concrete mix. Protect the concrete from direct sunlight and extreme temperatures during the curing process. Consider using a fiber-reinforced concrete mix for added strength and crack resistance.

Problem: The Post is Wobbling

* **Solution:** This usually indicates that the post hole is not deep enough or that the concrete has not been properly compacted. Dig a deeper hole and re-pour the concrete, ensuring it is thoroughly compacted around the post. You may also need to add more concrete to provide additional support.

Problem: Water Pooling Around the Post

* **Solution:** Slope the soil away from the post to prevent water from pooling around the base. You can also install a drainage system to divert water away from the fence. Consider using a gravel base under the concrete to improve drainage.

Maintaining Your Metal Fence Posts for Longevity

Proper maintenance is essential to ensure the longevity of your metal fence posts. Regular inspections and timely repairs can prevent minor problems from escalating into major issues. This section provides tips on how to maintain your fence posts and keep them in good condition for years to come.

Regular Inspections

Inspect your fence posts at least twice a year, preferably in the spring and fall. Look for signs of rust, corrosion, cracks, or leaning. Pay particular attention to the base of the posts, where they are most vulnerable to moisture and soil contact.

Rust Prevention

If you notice any rust on your metal fence posts, take immediate action to prevent it from spreading. Remove the rust with a wire brush or sandpaper, then apply a rust-inhibiting primer and paint. Consider using a galvanized steel post for superior rust resistance.

Concrete Repair

If the concrete around your fence posts is cracked or damaged, repair it promptly to prevent water from seeping in and corroding the metal. Use a concrete patching compound to fill the cracks and restore the concrete’s integrity. Ensure the patching compound is compatible with the existing concrete.

Soil Management

Keep the soil around your fence posts well-drained to prevent moisture buildup. Slope the soil away from the posts and consider installing a drainage system if necessary. Avoid planting vegetation too close to the posts, as this can trap moisture and promote corrosion.

Understanding the Cost of Setting Metal Fence Posts in Concrete

The cost of **setting metal fence posts in concrete** can vary depending on several factors, including the type of materials used, the size of the fence, and whether you hire a professional installer. Understanding these costs can help you budget effectively and make informed decisions.

Factors Affecting Cost

* **Materials:** The cost of metal fence posts, concrete mix, and other materials will vary depending on the quality and quantity required.

* **Labor:** If you hire a professional installer, labor costs will be a significant factor. These costs can vary depending on the installer’s experience and the complexity of the project.

* **Site Preparation:** If the site requires extensive clearing, grading, or excavation, this can add to the overall cost.

* **Permits:** Permit fees can vary depending on your location and the type of fence being installed.

Cost-Saving Tips

* **DIY Installation:** If you have the skills and experience, installing the fence yourself can save you a significant amount of money on labor costs.

* **Bulk Purchases:** Buying materials in bulk can often result in lower prices.

* **Compare Quotes:** Get quotes from multiple installers to ensure you are getting the best price.

* **Choose Affordable Materials:** While it’s important to use quality materials, you can often find affordable options that meet your needs.

Q&A: Expert Answers to Your Questions About Setting Metal Fence Posts in Concrete

Here are some frequently asked questions about **setting metal fence posts in concrete**, answered by our team of experienced fence installers:

- What is the best type of concrete to use for fence posts? Quick-setting concrete is often preferred for its convenience and faster curing time, but standard concrete mix provides excellent strength and durability. Fiber-reinforced concrete is a good option for added crack resistance.

- How deep should I dig the post holes? The depth of the post holes should be at least one-third the height of the post above ground. For example, a 6-foot fence post should have at least 2 feet of its length buried in concrete.

- How much concrete do I need for each post hole? The amount of concrete needed will depend on the diameter and depth of the post hole. A general rule of thumb is to allow for about 2-3 bags of 50-pound concrete mix per post hole.

- Can I use gravel instead of concrete? While gravel can provide some support, it does not offer the same level of stability and durability as concrete. Concrete is the preferred material for **setting metal fence posts in concrete** to ensure a long-lasting fence.

- How long does it take for concrete to cure? Concrete typically takes 24-48 hours to set enough to remove the braces, but it can take up to 7 days to fully cure and reach its maximum strength.

- What is the best way to prevent rust on metal fence posts? Use galvanized steel posts or apply a rust-inhibiting primer and paint to protect the metal from moisture and corrosion. Regular inspections and maintenance are also essential.

- How do I fix a leaning fence post? If the post is only slightly leaning, you may be able to straighten it by digging around the base and adding more concrete. If the post is severely leaning, you may need to replace it entirely.

- Can I set fence posts in concrete in the winter? Yes, but you will need to take extra precautions to protect the concrete from freezing. Use a concrete mix that is designed for cold weather and insulate the posts to prevent the concrete from freezing before it has a chance to cure.

- What are the signs that a fence post needs to be replaced? Signs that a fence post needs to be replaced include severe rust, corrosion, cracks, leaning, or wobbling. If the post is significantly damaged, it is best to replace it to prevent further damage to the fence.

- Is it better to hire a professional or DIY setting metal fence posts in concrete? This depends on your skill level, experience, and available time. If you are comfortable with DIY projects and have the necessary tools, you can save money by installing the fence yourself. However, if you are unsure or lack the time, hiring a professional installer is recommended to ensure a proper installation.

Conclusion: Building a Fence That Lasts

Setting metal fence posts in concrete is a crucial step in building a strong and durable fence. By following the steps outlined in this guide, you can ensure that your fence stands the test of time and provides lasting security and value. Remember to plan carefully, use quality materials, and take your time to ensure a proper installation. Our experience shows that a well-built fence is a worthwhile investment that enhances your property and provides peace of mind. Ready to start building? Share your experiences or questions about **setting metal fence posts in concrete** in the comments below!