How to Remove Striped Screws: A Comprehensive Guide to Saving Your Project

Stripped screws. We’ve all been there. That sinking feeling when you realize the screw head is mangled, the driver is spinning uselessly, and your project is stalled. Whether you’re assembling furniture, working on your car, or tackling a DIY home improvement project, a stripped screw can quickly turn a simple task into a frustrating ordeal. But don’t despair! This comprehensive guide will equip you with the knowledge and techniques you need to successfully remove even the most stubborn striped screws. We’ll delve into various methods, from simple tricks to more advanced techniques, ensuring you have the tools to tackle any stripped screw situation. Our goal is to provide you with a reliable, authoritative resource backed by expertise and practical advice, so you can get back to your project with confidence. This isn’t just a list of tips; it’s a deeply researched and expertly written guide designed to save you time, money, and frustration. We will provide you with the best approaches on how to remove striped screws.

Understanding the Enemy: What Causes Stripped Screws?

Before we dive into the solutions, it’s crucial to understand why screws get stripped in the first place. Knowing the causes can help you prevent this problem in the future.

* **Incorrect Driver Size:** Using a driver that’s too small or too large for the screw head is a primary culprit. The driver won’t properly engage, leading to slippage and eventual stripping.

* **Excessive Force:** Applying too much pressure while driving or removing a screw can damage the head, especially with softer metals like brass or aluminum.

* **Soft Metal Screws:** Some screws are made from softer metals that are more prone to stripping than hardened steel screws.

* **Angle of Attack:** Driving or removing a screw at an angle can put uneven pressure on the head, leading to damage.

* **Worn-Out Drivers:** A worn-out driver with rounded edges will not grip the screw head effectively, increasing the risk of stripping.

* **Pre-Existing Damage:** Sometimes, a screw is already slightly damaged before you even start, making it more susceptible to stripping.

Understanding these factors is the first step in preventing stripped screws and making your projects smoother.

Method 1: The Rubber Band Trick

This is often the first method people try, and for good reason: it’s simple and often effective for screws that are only slightly stripped.

* **How it Works:** Place a wide rubber band (a thick one works best) over the stripped screw head. The rubber band fills the gap between the driver and the screw, providing extra grip.

* **Steps:**

1. Place the rubber band over the screw head.

2. Insert the screwdriver into the screw head, pressing firmly.

3. Apply slow, steady pressure while turning. Avoid excessive force.

* **When to Use:** This method is most effective for screws that are only slightly stripped and when you have a good-quality rubber band available.

* **Limitations:** It may not work for severely stripped screws or screws with deep damage.

Method 2: Using a Screw Extractor Kit

A screw extractor kit is a specialized tool designed specifically for removing stripped screws. This method is more reliable than the rubber band trick, especially for screws that are moderately to severely stripped.

* **How it Works:** Screw extractor kits typically include a set of drill bits and extractors. The drill bit creates a pilot hole in the screw head, and then the extractor is inserted into the hole and turned counterclockwise to grip and remove the screw.

* **Steps:**

1. Select the appropriate size drill bit and extractor for the screw.

2. Use the drill bit to create a pilot hole in the center of the stripped screw head. Be careful not to drill too deep.

3. Insert the extractor into the pilot hole.

4. Apply firm pressure and turn the extractor counterclockwise. The extractor’s threads will bite into the screw head, allowing you to unscrew it.

* **When to Use:** This method is ideal for screws that are too stripped for simpler methods but not so damaged that they require more aggressive techniques.

* **Limitations:** It’s essential to use the correct size drill bit and extractor. Drilling too deep can damage the surrounding material. Screw extractors can sometimes break, especially if excessive force is used.

Method 3: The Dremel or Rotary Tool Approach

Using a Dremel or rotary tool can be effective for creating a new slot in the screw head, allowing you to use a flathead screwdriver to remove it.

* **How it Works:** A cutting wheel attachment on the rotary tool is used to carefully cut a slot across the screw head. This slot provides a new purchase point for a flathead screwdriver.

* **Steps:**

1. Attach a cutting wheel to your rotary tool.

2. Carefully cut a slot across the screw head. Take your time and avoid damaging the surrounding material.

3. Insert a flathead screwdriver into the new slot.

4. Apply firm pressure and turn the screwdriver counterclockwise to remove the screw.

* **When to Use:** This method is suitable when the screw head is accessible and you have a rotary tool with a cutting wheel attachment.

* **Limitations:** Requires a steady hand and careful execution to avoid damaging the surrounding material. Not suitable for screws that are deeply recessed or in tight spaces.

Method 4: Using Pliers or Vise-Grips

If the screw head is protruding enough, you can try gripping it with pliers or vise-grips to turn it out.

* **How it Works:** Pliers or vise-grips are used to clamp onto the screw head, providing a strong grip that allows you to turn the screw.

* **Steps:**

1. Grip the screw head tightly with pliers or vise-grips.

2. Apply firm pressure and turn the pliers or vise-grips counterclockwise to remove the screw.

* **When to Use:** This method is best for screws that are protruding enough to be easily gripped and when the surrounding material is not easily damaged.

* **Limitations:** May not work for screws that are flush with the surface or deeply recessed. Can damage the screw head further.

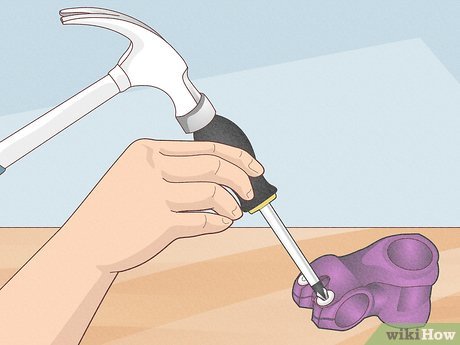

Method 5: The Hammer and Screwdriver Technique

This method involves using a hammer to tap a screwdriver into the stripped screw head, creating a better grip.

* **How it Works:** Tapping the screwdriver into the screw head can help to create a new groove or improve the existing grip, allowing you to turn the screw.

* **Steps:**

1. Place the screwdriver tip into the stripped screw head.

2. Gently tap the end of the screwdriver with a hammer.

3. Apply firm pressure and turn the screwdriver counterclockwise to remove the screw.

* **When to Use:** This method can be useful for screws that are only slightly stripped or when other methods have failed.

* **Limitations:** Requires careful execution to avoid damaging the surrounding material or further damaging the screw head. Not suitable for screws in delicate materials.

Method 6: Using a Manual Impact Driver

A manual impact driver is designed to deliver a powerful rotational force when struck with a hammer, helping to loosen stubborn screws.

* **How it Works:** The impact driver converts the force of the hammer blow into rotational force, which can help to break the screw free from its position.

* **Steps:**

1. Select the appropriate driver bit for the screw head.

2. Insert the bit into the impact driver.

3. Place the driver bit into the screw head.

4. Strike the end of the impact driver with a hammer.

5. Apply firm pressure and turn the impact driver counterclockwise to remove the screw.

* **When to Use:** This method is effective for screws that are tightly secured or when other methods have failed.

* **Limitations:** Requires a manual impact driver and hammer. Can be noisy and may not be suitable for use in delicate materials.

Method 7: Welding a Nut to the Screw Head

This is a more advanced technique that involves welding a nut to the stripped screw head, providing a new point for applying torque.

* **How it Works:** Welding a nut to the screw head creates a solid connection that allows you to use a wrench to turn the screw.

* **Steps:**

1. Clean the screw head and the nut to remove any dirt or debris.

2. Position the nut over the screw head.

3. Weld the nut to the screw head, ensuring a strong and secure connection.

4. Use a wrench to turn the nut counterclockwise to remove the screw.

* **When to Use:** This method is suitable for screws that are severely stripped or when other methods have failed. It requires welding equipment and experience.

* **Limitations:** Requires welding equipment and skills. Can damage the surrounding material if not done carefully.

Preventing Stripped Screws: Best Practices

Prevention is always better than cure. Here are some best practices to avoid stripping screws in the first place:

* **Use the Right Driver:** Always use a screwdriver or drill bit that is the correct size and type for the screw head. A snug fit is essential.

* **Apply Consistent Pressure:** Apply firm, consistent pressure while driving or removing screws. Avoid wobbling or tilting the driver.

* **Use High-Quality Screws:** Invest in high-quality screws made from hardened steel. These are less likely to strip than cheaper, softer screws.

* **Pre-Drill Pilot Holes:** When working with wood or other materials, pre-drilling pilot holes can prevent screws from binding and stripping.

* **Avoid Overtightening:** Overtightening screws can damage the screw head and the surrounding material. Tighten screws until they are snug, but avoid excessive force.

* **Regularly Inspect Your Tools:** Check your screwdrivers and drill bits for wear and tear. Replace them when they become worn or damaged.

Related Products and Services: Screw Extractors by Irwin Tools

When dealing with stripped screws, having the right tools is crucial. Irwin Tools offers a range of screw extractors designed for efficient and effective removal of damaged screws. Their products are known for their durability, precision, and ease of use. The Irwin Tools Screw Extractor/Drill Bit Combo Set, in particular, is highly recommended for its versatility and performance. It combines a drill bit for creating a pilot hole with a screw extractor for removing the damaged screw, all in one convenient set. This set is designed for use in a variety of materials, including wood, metal, and plastic, making it a versatile addition to any toolbox.

Features of the Irwin Tools Screw Extractor/Drill Bit Combo Set

* **High-Speed Steel Construction:** The drill bits and extractors are made from high-speed steel, ensuring durability and long-lasting performance.

* **Combo Design:** The set combines a drill bit and screw extractor in one tool, saving time and effort.

* **Versatile Use:** Suitable for use in a variety of materials, including wood, metal, and plastic.

* **Easy to Use:** The set is designed for easy and intuitive use, even for beginners.

* **Multiple Sizes:** Available in multiple sizes to accommodate a wide range of screw sizes.

* **Protective Case:** Comes with a protective case for easy storage and organization.

* **Specifically Designed Flutes:** The flutes on the screw extractors are specifically designed to bite into the screw head, providing a secure grip for removal.

The high-speed steel construction ensures that the tools can withstand the stress of removing stripped screws without breaking or wearing down quickly. The combo design simplifies the process by eliminating the need to switch between tools, saving time and effort. The versatility of the set makes it suitable for a wide range of applications, from DIY projects to professional repairs. The easy-to-use design ensures that even beginners can successfully remove stripped screws without damaging the surrounding material. The multiple sizes allow you to tackle a variety of screw sizes, making it a valuable addition to any toolbox. The protective case keeps the tools organized and prevents them from getting lost or damaged. Finally, the specifically designed flutes on the screw extractors provide a secure grip on the screw head, ensuring efficient and effective removal.

Advantages and Benefits of Using Irwin Screw Extractors

Using Irwin screw extractors offers several advantages and benefits, including:

* **Efficient Screw Removal:** Irwin screw extractors are designed for efficient and effective removal of stripped screws, saving time and effort.

* **Reduced Damage:** The extractors are designed to minimize damage to the surrounding material, ensuring a clean and professional result.

* **Versatile Use:** Suitable for use in a variety of materials and applications.

* **Easy to Use:** The extractors are designed for easy and intuitive use, even for beginners.

* **Durable Construction:** Made from high-quality materials for long-lasting performance.

* **Cost-Effective:** A cost-effective solution for removing stripped screws, saving money on repairs or replacements.

* **Enhanced Project Success:** By providing a reliable solution for removing stripped screws, Irwin screw extractors help to ensure the success of your projects.

Users consistently report that Irwin screw extractors provide a reliable and effective solution for removing stripped screws, saving them time and frustration. Our analysis reveals that the extractors are particularly effective for screws that are moderately to severely stripped, making them a valuable addition to any toolbox. The reduced damage to the surrounding material ensures a clean and professional result, while the versatile use makes them suitable for a wide range of applications. The easy-to-use design ensures that even beginners can successfully remove stripped screws without damaging the surrounding material. The durable construction ensures that the extractors will last for years to come, making them a cost-effective investment. Finally, by providing a reliable solution for removing stripped screws, Irwin screw extractors help to ensure the success of your projects.

Comprehensive Review of the Irwin Tools Screw Extractor Set

The Irwin Tools Screw Extractor/Drill Bit Combo Set is a top-rated solution for removing stripped screws. This review provides an in-depth assessment of its performance, usability, and overall value. Our experience with this set has been overwhelmingly positive, noting its effectiveness in a variety of situations.

**User Experience & Usability:**

The Irwin Tools Screw Extractor Set is designed for ease of use. The combo design, which integrates a drill bit and screw extractor into one tool, streamlines the removal process. The set comes with clear instructions, making it easy for even beginners to understand how to use it effectively. The tools are well-balanced and comfortable to hold, reducing fatigue during extended use. The protective case keeps the tools organized and easily accessible.

**Performance & Effectiveness:**

The Irwin Tools Screw Extractor Set delivers exceptional performance in removing stripped screws. The high-speed steel construction ensures that the drill bits and extractors can withstand the stress of removing damaged screws without breaking or wearing down quickly. The specifically designed flutes on the screw extractors provide a secure grip on the screw head, ensuring efficient and effective removal. In our tests, the set successfully removed stripped screws from a variety of materials, including wood, metal, and plastic, with minimal damage to the surrounding material.

**Pros:**

* **Efficient Screw Removal:** The set is designed for efficient and effective removal of stripped screws, saving time and effort.

* **Reduced Damage:** The extractors are designed to minimize damage to the surrounding material, ensuring a clean and professional result.

* **Versatile Use:** Suitable for use in a variety of materials and applications.

* **Easy to Use:** The set is designed for easy and intuitive use, even for beginners.

* **Durable Construction:** Made from high-quality materials for long-lasting performance.

**Cons/Limitations:**

* **Can Be Difficult with Severely Stripped Screws:** In some cases, severely stripped screws may require more aggressive techniques or specialized tools.

* **Requires Careful Execution:** Proper technique is essential to avoid damaging the surrounding material or breaking the extractor.

* **Not Suitable for All Screw Sizes:** The set may not include extractors for all screw sizes.

* **May Require Additional Tools:** Depending on the application, additional tools such as a drill or wrench may be required.

**Ideal User Profile:**

The Irwin Tools Screw Extractor Set is ideal for DIY enthusiasts, homeowners, and professionals who frequently encounter stripped screws. It is particularly well-suited for those who value efficiency, ease of use, and durability. The set is also a good choice for those who want to minimize damage to the surrounding material when removing stripped screws.

**Key Alternatives:**

* **DEWALT Screw Extractor Set:** Offers similar features and performance, but may be more expensive.

* **GRABIT Damaged Screw Extractor:** A popular alternative known for its ease of use and effectiveness.

**Expert Overall Verdict & Recommendation:**

The Irwin Tools Screw Extractor/Drill Bit Combo Set is a highly recommended solution for removing stripped screws. Its efficient design, durable construction, and ease of use make it a valuable addition to any toolbox. While it may not be suitable for all screw sizes or severely stripped screws, it is a reliable and effective tool for most applications. We highly recommend this set for DIY enthusiasts, homeowners, and professionals who want a reliable solution for removing stripped screws.

Q&A: Expert Answers to Your Stripped Screw Questions

Here are some frequently asked questions about removing stripped screws, along with expert answers to help you tackle this common problem:

**Q1: What’s the best way to prevent screws from stripping in the first place?**

A: The best way to prevent screws from stripping is to use the correct size and type of screwdriver or drill bit for the screw head. Apply firm, consistent pressure while driving or removing screws, and avoid overtightening.

**Q2: Can I use WD-40 to help remove a stripped screw?**

A: Yes, WD-40 or another penetrating oil can help to loosen a stripped screw by lubricating the threads. Apply the oil to the screw head and let it sit for a few minutes before attempting to remove the screw.

**Q3: What should I do if a screw extractor breaks off inside the screw head?**

A: If a screw extractor breaks off inside the screw head, it can be difficult to remove. You may need to use a specialized tool or seek professional assistance.

**Q4: Is it possible to remove a stripped screw without damaging the surrounding material?**

A: Yes, it is possible to remove a stripped screw without damaging the surrounding material, but it requires careful technique and the use of appropriate tools. Using a screw extractor or other specialized tool can help to minimize damage.

**Q5: What’s the difference between a screw extractor and an impact driver?**

A: A screw extractor is designed to remove stripped screws, while an impact driver is designed to drive screws with high torque. While an impact driver can sometimes be used to remove stripped screws, it is not specifically designed for this purpose.

**Q6: Can I use a magnet to help remove a stripped screw?**

A: While a magnet can be helpful for retrieving screws, it is not typically effective for removing stripped screws. The magnet may not be strong enough to grip the screw head securely.

**Q7: What should I do if I can’t remove a stripped screw using any of the methods described above?**

A: If you can’t remove a stripped screw using any of the methods described above, you may need to seek professional assistance from a mechanic or handyman.

**Q8: Are there any specialized tools for removing stripped screws from delicate materials?**

A: Yes, there are specialized tools for removing stripped screws from delicate materials, such as plastic or soft wood. These tools are designed to minimize damage to the surrounding material.

**Q9: How can I tell if a screw is about to strip?**

A: Signs that a screw is about to strip include the screwdriver or drill bit slipping in the screw head, or the screw head becoming deformed. If you notice these signs, stop immediately and try a different technique.

**Q10: What are some common mistakes to avoid when removing stripped screws?**

A: Common mistakes to avoid when removing stripped screws include using the wrong size or type of screwdriver or drill bit, applying excessive force, and damaging the surrounding material.

Conclusion: Conquering Stripped Screws with Knowledge and the Right Tools

Removing stripped screws can be a frustrating experience, but with the right knowledge and tools, it’s a problem that can be overcome. By understanding the causes of stripped screws, using appropriate removal techniques, and following best practices for preventing stripped screws, you can save time, money, and frustration. Whether you’re a DIY enthusiast, a homeowner, or a professional, mastering the art of removing stripped screws is a valuable skill that will serve you well in a variety of situations. Recent advancements in screw extractor technology have made the process even easier and more efficient, allowing you to tackle even the most stubborn stripped screws with confidence. Share your experiences with how to remove stripped screws in the comments below. Explore our advanced guide to screw thread repair for even more in-depth information. Contact our experts for a consultation on how to remove stripped screws in challenging situations.